Introduction

Styrofoam is a widely used material in packaging, construction, and insulation. But there’s a lot of confusion around what it actually is. Many people use “Styrofoam” interchangeably with expanded polystyrene (EPS) or extruded polystyrene (XPS), assuming they’re all the same thing. While they share similarities, they’re not identical—and the differences matter, especially in industrial applications.

In this article, we’ll break it all down—the real definition of Styrofoam, its industrial applications, and the environmental impact.

Table of Contents

What is Styrofoam?

Styrofoam is a brand name that refers to extruded polystyrene foam (XPS), a rigid, dense material different from expanded polystyrene (EPS). Styrofoam is commonly recognized in GCC markets for its role in insulation boards, packaging materials, and disposable food products. Due to its manufacturing process, Styrofoam is denser and offers better moisture resistance than EPS, making it ideal for construction and packaging solutions in hot climates.

How Did Styrofoam Come About?

Styrofoam has been in use since the 1940s. Today, it’s a well-known material used in construction, foodservice, and packaging industries. While Styrofoam has become a generic term for all types of foam, it technically refers to extruded polystyrene (XPS), which differs from expanded polystyrene (EPS).

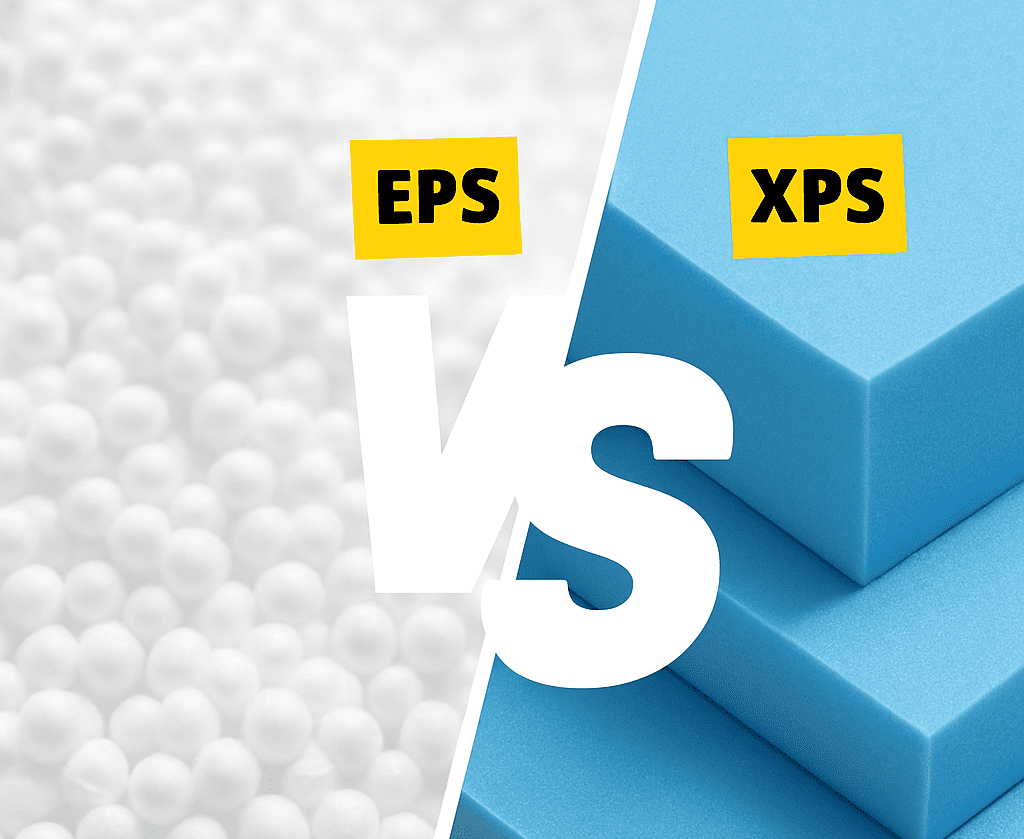

Styrofoam vs EPS: What’s the Difference?

Styrofoam or polystyrene (EPS) might look alike, but they differ significantly in their composition, insulation properties, and durability. Here’s a quick comparison:

- Composition:

- Styrofoam (XPS): Made from extruded polystyrene, Styrofoam is a rigid, dense foam with a smooth texture. It is commonly used in construction and high-performance insulation.

- EPS (Expanded Polystyrene): Made from polystyrene beads, EPS can be produced in different shapes. It is commonly used in insulation, geofoam, and packaging applications.

- Insulation Properties:

- Styrofoam (XPS): Offers superior insulation, especially in high-moisture environments, due to its closed-cell structure.

- EPS (Expanded Polystyrene): EPS (Expanded Polystyrene): Offers good insulation properties and is more commonly used for wall insulation..

- Durability:

- Styrofoam (XPS): More durable and resistant to moisture, making it ideal for construction and long-term insulation.

- EPS (Expanded Polystyrene): Available in a wide range of densities, making it versatile for various applications.

Read more:

Styrofoam vs Thermocol: Are They the Same?

Thermocol is another name for EPS (Expanded Polystyrene), . The key Differences Between EPS (Thermocol) and XPS (Styrofoam) are:

Composition and Process:

- Styrofoam (XPS): Produced through an extrusion process, it comes in a rigid sheets.

- Thermocol (EPS): Made from expanded polystyrene beads, Thermocol can be produced in large blocks as well as custom shapes to suit different applications

- Durability and Uses:

- Styrofoam (XPS): Durable, resistant to moisture, and suitable for roof and floor insulation.

- Durable and versatile, commonly used in Geofoam, decoration, packaging, and disposable food containers

Here’s a quick comparison table to highlight the key differences and similarities between Styrofoam and EPS for better clarity.

| Features | Styrofoam (XPS) | Expanded Polystyrene (EPS) |

|---|---|---|

| Base Material | Polystyrene | Polystyrene |

| Manufacturing Process | Extrusion | Expansion |

| Texture | Finer, closed-cell structure | Closed-cell structure |

| Insulating Properties | High | High |

| Brand | FORMA | FORMA |

| Density | 32-48kg/m3 | 12-46kg/m3 |

Through this comparative lens, we can understand the differences between XPS and EPS, despite their common ancestry.

Properties of Styrofoam: What Makes It Unique?

Styrofoam stands out for its lightweight, durable, and excellent insulating properties. Its closed-cell structure makes it moisture-resistant and more effective for Thermal and moisture insulation . Whether used in building insulation Styrofoam’s denser, more rigid texture provides superior protection.

Forma Insulation offers premium Styrofoam solutions that suit the extreme GCC climate.

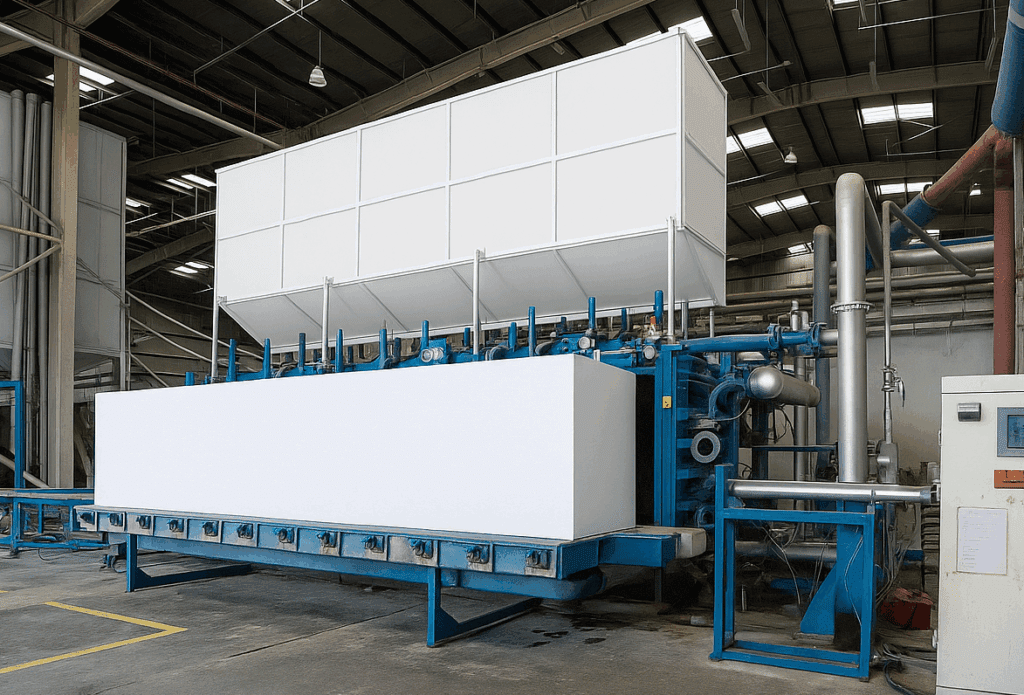

How Is Styrofoam (XPS Polystyrene Foam) Made?

The production process for Styrofoam involves the following steps:

- Extrusion: Polystyrene pellets are melted and mixed with additives to enhance certain properties, such as rigidity and durability. The molten mixture is then extruded through a die, forming continuous sheets or boards of foam.

- Cooling and Shaping: As the extruded foam passes through the die, it undergoes rapid cooling, which solidifies the foam into its final shape. The foam is then cut into sheets as needed for various applications.

- Finishing: After shaping, the Styrofoam products may undergo additional processes such as surface finishing or edge cutting to improve the performance.

What Is Styrofoam Used For? (Construction, Insulation & More in the GCC)

In the GCC, Styrofoam is commonly used for:

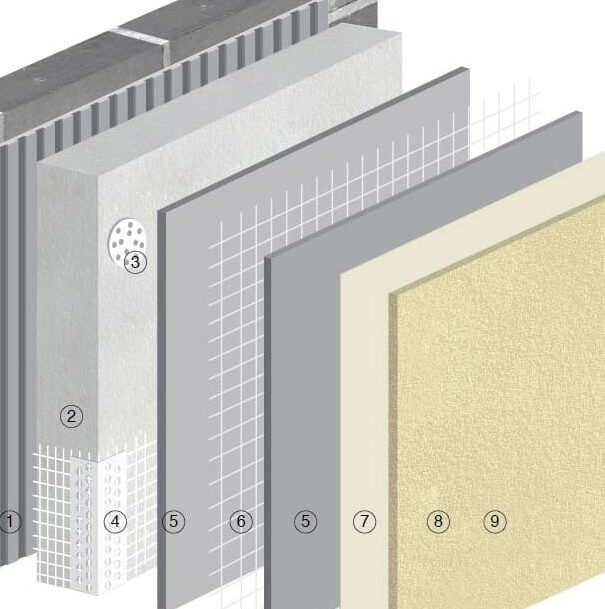

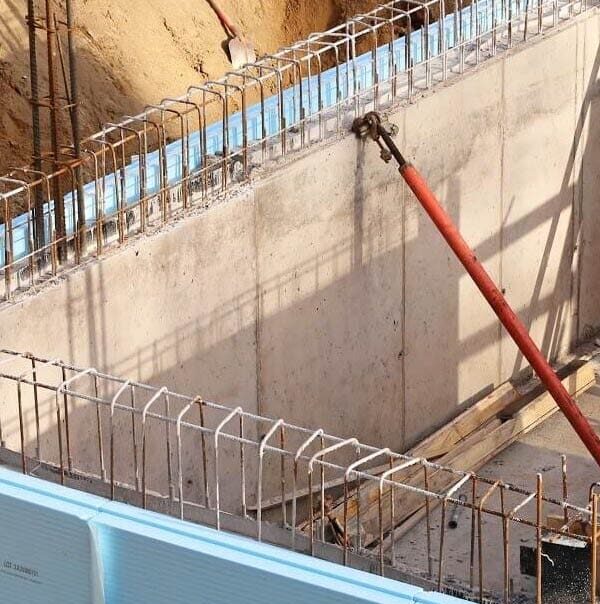

- Building insulation: Styrofoam boards XPS are an excellent choice for roof, and foundation insulation, especially in the harsh heat of the GCC region.

Extruded Polystyrene

Can Styrofoam Be Recycled?

Yes, Styrofoam can be recycled, converting it into reusable materials for construction, packaging, or even eco-friendly products. This helps mitigate environmental impact and encourage circular economy practices.

Styrofoam Regulations & Standards in the GCC

Each GCC country has varying regulations regarding the use of Styrofoam.

Top Polystyrene & Styrofoam Manufacturers in the GCC

For premium Styrofoam XPS & Expanded polystyrene EPS products in the GCC region, look no further than FORMA Insulation. We specialize in providing high-quality Styrofoam solutions for construction, insulation and packaging industries. Our foam products are engineered to withstand the region’s extreme temperatures, providing excellent insulation and protection.

FORMA Insulation stands out as the premier choice for Polystyrene Styrofoam manufacturing in GCC, setting the standard as the largest Polystyrene Styrofoam manufacturer and the most reliable EPS supplier in the GCC.

Final Thoughts on Styrofoam in the GCC

Styrofoam plays a crucial role in the GCC region due to its excellent insulating properties and versatility in various industries. By choosing high-quality Styrofoam for your projects and adopting sustainable practices, you can ensure your contributions to the region’s development are both effective and environmentally responsible.

FAQs

Q: What is another name for Styrofoam?

In the GCC, EPS (Expanded Polystyrene) is most commonly referred to simply as “foam.” The term “Styrofoam” is used in reference to extruded polystyrene. It is often used as a general term for all forms of extruded polystyrene and even sometime for Expanded Polystyrene .

Q: Is Styrofoam the same as thermocol?

No, Styrofoam and thermocol are often confused, but they are not the same. Styrofoam is made from extruded polystyrene (XPS), while thermocol “EPS” is made from expanded polystyrene (EPS), with different insulation properties .

Q: Is EPS the same as Styrofoam?

No, EPS (Expanded Polystyrene) and Styrofoam (XPS) are different. Styrofoam is made from extruded polystyrene (XPS), whereas EPS is made from expanded polystyrene, which forms foam blocks by expanding tiny beads of polystyrene. Styrofoam forms in sheets.

Q: What is Styrofoam used for?

Styrofoam is commonly used for insulation, floor, Roofs.

Q: What are Styrofoam sheets called?

Styrofoam sheets are commonly called extruded polystyrene (XPS) sheets, or expanded polystyrene (EPS) sheets depending on the type. While many people use “Styrofoam” as a general term, true Styrofoam is XPS product, primarily used for insulation. EPS sheets, on the other hand, are more commonly used in packaging, insulation, Geofoam and construction.