Introduction

If you’re looking for a lightweight, durable material for construction, packaging, or insulation, expanded polystyrene (EPS) is a great choice. In this article, we’ll walk you through how it’s made, what makes it so useful, and where you can find it. Keep reading to see how EPS can work for you!

Table of Contents

So, What Exactly is Expanded Polystyrene (EPS) ?

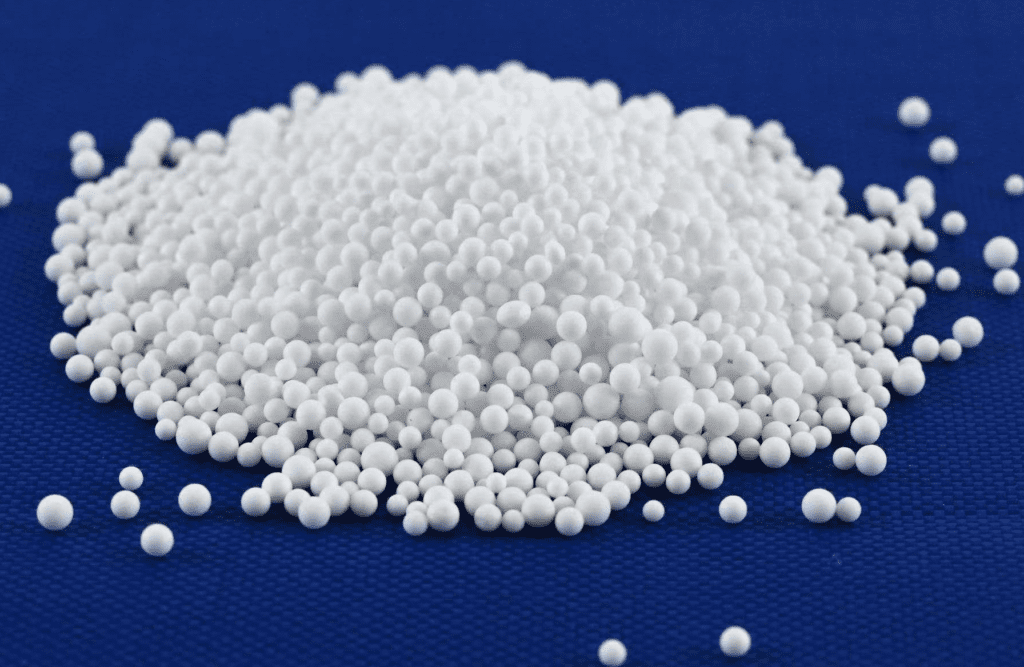

If you’re not already familiar with Expanded Polystyrene (EPS), it’s basically that light, spongy material you see everywhere – whether it’s the foam inside packaging or the stuff used for insulation in buildings. In the GCC, people might call it Styrofoam, Polystyrene Foam, or just foam. They’re all referring to the same thing, but the names can change depending on who you’re talking to. EPS is made from tiny beads of polystyrene that expand when heated, so it’s super light but still strong enough to provide insulation or protect things during shipping.

How Did Expanded Polystyrene Come About?

EPS wasn’t invented yesterday. It’s been around since the 1930s and has been used in all kinds of industries ever since. In the GCC, a lot of people know it as Styrofoam (yes, like the cups and packaging), and it’s commonly used for insulation in buildings or to protect fragile goods during shipping. No matter what you call it, though, EPS, Styrofoam, or Polystyrene Foam all do pretty much the same thing: they help keep things cool or safe.

What Makes Expanded Polystyrene So Special?

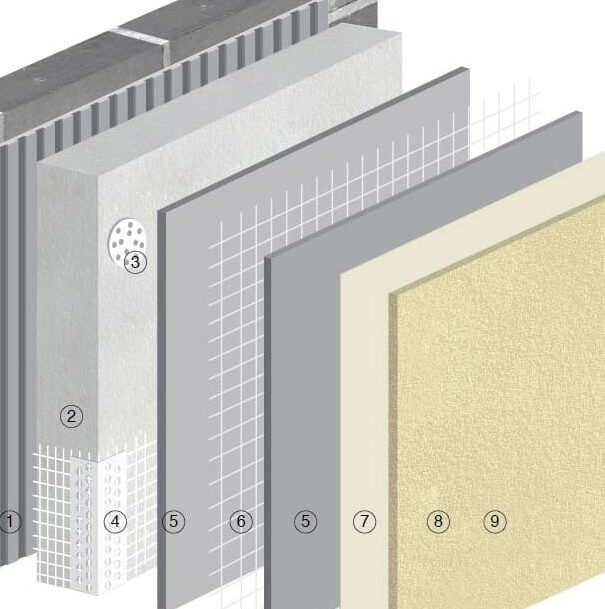

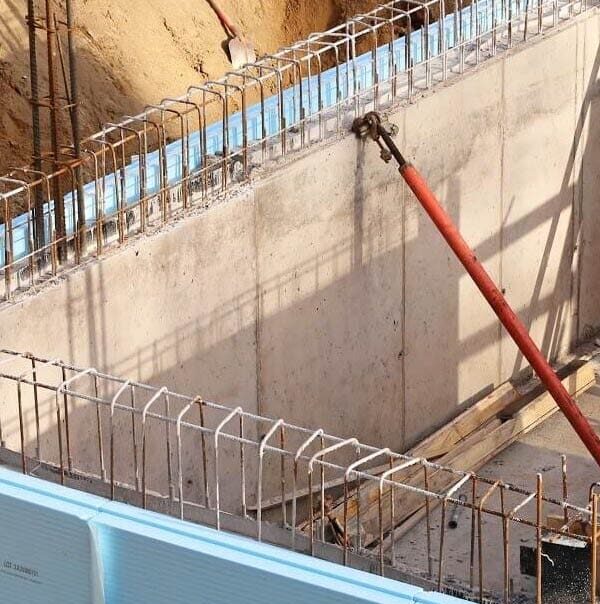

One reason people love EPS (or Styrofoam or Polystyrene Foam) is because it’s incredibly light. In fact, it’s made up of around 98% air, which is why it’s such a great material for insulation. Even though it’s light, EPS is durable and can keep buildings cool by reducing heat transfer – which is perfect for places like the GCC, where the weather is extremely hot. Whether it’s used in insulation for walls, ceilings, or floors, or even as part of the road construction, Polystyrene Foam plays a huge role in the region’s construction industry.

How Do They Make Expanded Polystyrene?

To make EPS, it starts with small polystyrene beads. These beads are heated, causing them to expand and form foam. After they’re expanded, the beads are allowed to mature and then are molded into different shapes for various uses, like foam blocks or insulation sheets. It’s a simple but effective process that turns small beads into something incredibly useful and versatile.

What’s Expanded Polystyrene Used For in the GCC?

There’s no shortage of uses for EPS in the GCC. Most commonly, it’s used in construction for insulation, helping to reduce energy consumption in buildings. With the intense heat in the region, EPS is perfect for keeping buildings cool and reducing air conditioning costs. It’s also used in packaging – that’s the Styrofoam you see protecting items like electronics and food during shipping. Plus, it’s used in a lot of roadwork, where it helps keep embankments lightweight.

Environmental Impact: Is Expanded Polystyrene Bad for the Planet?

One of the big questions surrounding EPS, or Styrofoam, is whether it’s bad for the environment. The truth is, EPS can be a bit of a pain when it comes to disposal because it doesn’t break down easily. But don’t worry – it’s recyclable. And with more focus on sustainability in the GCC, there’s a growing push to recycle EPS and use it in ways that help the environment, like in building materials or energy recovery plants.

Can Expanded Polystyrene Be Recycled?

Yes! EPS can be recycled, but it’s not done as often as other materials. Some countries in the GCC, like Saudi Arabia and the UAE, are working on improving EPS recycling programs, and companies are getting more creative with how they reuse the material. It’s sometimes turned into new products or used to create lightweight concrete blocks or improve soil conditions for farming. The focus is slowly shifting toward making sure EPS doesn’t just end up in landfills.

Regulations and Standards for Expanded Polystyrene in the GCC

Each country in the GCC has its own rules when it comes to using EPS. For example, in Saudi Arabia, the government sets standards for how EPS should be used in construction projects, making sure it meets certain safety and insulation requirements. The same goes for places like Dubai, where EPS is used as part of the Green Building Regulations. These standards help ensure that EPS is used in ways that make buildings more energy-efficient and less harmful to the environment.

Some key regulations include:

- Saudi Standards, Metrology and Quality Organization (SASO) – Governs EPS use in construction.

- Dubai Municipality Green Building Regulations – Promotes EPS insulation for energy efficiency.

- Qatar Construction Standards (QCS) – Specifies thermal performance requirements for EPS insulation.

Where Can You Get Expanded Polystyrene in the GCC?

If you’re looking for the best EPS or Styrofoam products in the GCC region, Forma Insulation is the leading expanded polystyrene manufacturer and supplier of Polystyrene Foam. We specialize in providing high-quality EPS solutions tailored for the construction and packaging industries. Our products are designed to meet the specific needs of the harsh climate in Saudi Arabia, UAE, and Qatar, offering superior thermal insulation, durability, and performance.

Whether you’re in Saudi Arabia, the UAE, or Qatar, Forma Insulation is the trusted name for premium EPS. Our custom solutions ensure that you receive the highest standard of Polystyrene Foam to support your projects, whether it’s for thermal insulation, packaging, or lightweight construction applications.

When it comes to sourcing EPS in the GCC, Forma Insulation is your go-to manufacturer for quality, reliability, and sustainability.

Final Thoughts on Expanded Polystyrene in the GCC

If you’re planning to use EPS, Styrofoam, or Polystyrene Foam in your construction or packaging projects in the GCC, it’s important to know all the different names people use for it. These materials are super important in the region, and understanding their properties and uses will help you make better choices for your projects. By focusing on things like sustainability and recycling, you’ll also be able to do your part in making sure EPS stays useful without harming the planet.

FAQs

Q: Is EPS insulation suitable for the GCC climate?

A: Yes, EPS provides excellent thermal insulation, reducing cooling costs, especially in extreme temperatures.

Q: Can EPS be recycled in the GCC?

A: Yes, many recycling facilities across the GCC accept EPS for mechanical or energy recovery.

Q: Is EPS environmentally friendly?

A: While EPS is a plastic, its energy efficiency benefits and recyclability make it a sustainable choice when managed properly.