Introduction

There are several factors to consider when aiming to keep your building cool and comfortable. First and foremost, a building must have an effective envelope with the right thermal insulation materials. By minimizing heat transfer through the building envelope, you can significantly reduce the energy needed to maintain a comfortable indoor climate. Thermal insulation not only prevents heat transfer but also helps control sound. So, here is a best thermal insulation materials list that are put together that keep your building cooler and more energy-efficient.

Table of Contents

Why Is Thermal Insulation Important?

Insulation materials play a crucial role in thermal insulation, aiming to minimize heat transfer between objects. Heat transfer poses challenges across various industries when objects in contact have disparate temperatures. Although heat flow between these objects is inevitable, the use of insulation materials becomes instrumental in curbing the transfer. These materials function by diminishing thermal conduction or redirecting thermal radiation rather than absorbing it.

One common type of thermal insulation material is foam insulation, available in various forms such as expanded polystyrene (EPS), extruded polystyrene (XPS), and polyurethane foam. These materials boast low thermal conductivity and are often utilized in construction to insulate walls, roofs, and floors. In addition to temperature control, insulation also plays a key role in soundproofing, reducing noise pollution—a common issue in bustling cities like Dubai, Riyadh, and Doha.

GCC Insulation Materials Market Overview

The GCC building insulation materials market is witnessing transformative trends driven by key drivers that reflect a growing emphasis on energy efficiency and sustainable construction practices in the region. With rising temperatures in the GCC and increasing emphasis on energy efficiency, the demand for high-quality insulation materials is growing. Government regulations and green building standards, such as the UAE’s Estidama and Saudi Arabia’s Saudi Green Building Forum, promote energy-efficient construction practices. This makes the selection of appropriate thermal insulation materials even more crucial for businesses and homeowners looking to reduce their carbon footprint and energy costs.

How to Choose the Right Thermal Insulation Material for Your Project

Selecting the ideal thermal insulation material for your construction project is critical to ensuring energy efficiency, durability, and comfort, especially in the extreme climate of the GCC. Here are key factors to consider when choosing the most suitable insulation material:

1. Thermal Resistance (R-Value)

The R-value indicates the material’s ability to resist heat flow. A higher R-value means better insulation performance. For hot climates like Saudi Arabia, prioritize materials with high R-values to effectively block heat transfer.

2. Fire Resistance

Fire safety is a crucial consideration in any construction project. Materials like Rock Wool and polystyrene-based insulation (EPS/XPS) offer excellent fire resistance, making them suitable for residential and commercial applications.

3. Moisture Resistance

Humidity can compromise the performance of insulation. Choose materials like extruded polystyrene (XPS), which is known for its superior moisture resistance, especially in regions prone to high humidity.

4. Cost-Effectiveness

Budget is always a determining factor. Materials like expanded polystyrene (EPS) provide a balance between affordability and insulation efficiency, making them ideal for projects with limited budgets.

5. Application Versatility

Different materials perform better in specific applications:

- Walls and Roofs: Polystyrene insulation (XPS or EPS) is lightweight and easy to install.

- High Fire Resistance Needs: Rock Wool excels in areas requiring enhanced fireproofing.

- Affordable and Widely Available Solutions: Fiberglass insulation is suitable for low-cost projects.

6. Environmental Impact

Consider the sustainability of the material. Materials like polystyrene can be recycled, reducing environmental impact, while others may have a lower carbon footprint during manufacturing.

Every project has unique requirements, and selecting the right insulation material involves balancing performance, cost, and specific project needs. For tailored advice and high-quality insulation solutions, contact our team of experts today!

Common Types of Thermal Insulation Materials

Here is a list of the common types of effective insulation materials, which are well-suited for the unique climate conditions of the GCC, offering excellent thermal performance and long-term savings:

1. Expanded Polystyrene (EPS)

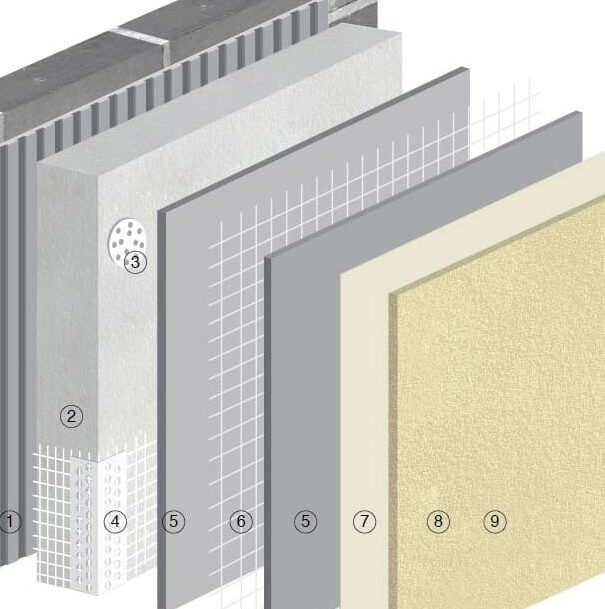

EPS is a closed-cell, rigid insulation material produced by expanding and fusing polystyrene beads. It is a cost-effective and lightweight solution widely utilized in construction for thermal insulation applications, including concrete roof tiles and insulation boards. Proper installation is crucial to mitigate bead dispersion from mechanical damage or air leakage.

Composition: Manufactured from pre-expanded polystyrene beads derived from styrene monomers.

R-Value: Delivers moderate to high R-values, ensuring dependable thermal resistance.

Environmental Impact: EPS is 100% recyclable.

Form: Supplied in rigid board configurations for versatile application.

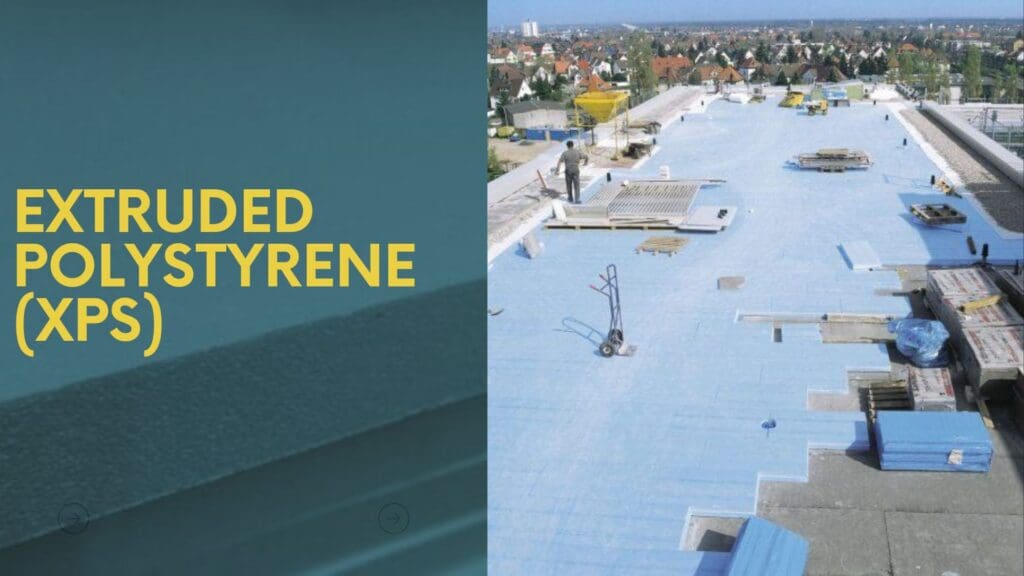

2. Extruded Polystyrene (XPS)

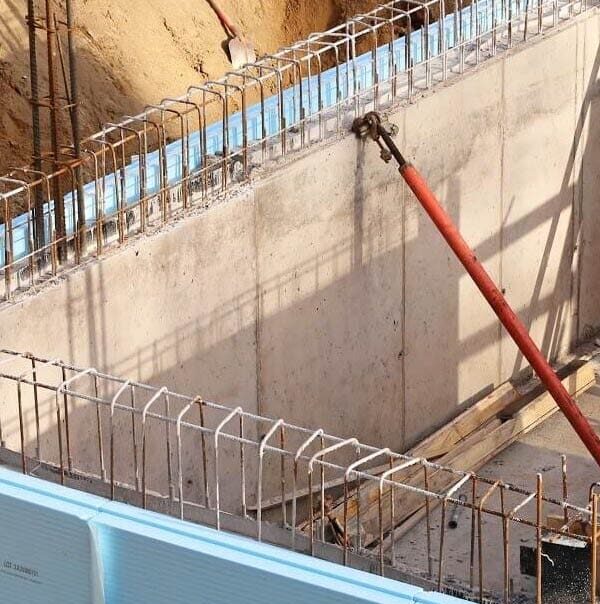

Extruded polystyrene (XPS) differs from EPS due to its production process. It starts as a molten substance, later molded into sheets, and is primarily used in foam board insulation. XPS is resistant to moisture, corrosion, and rotting, which makes it effective in maintaining structural integrity.

Composition: Molten polystyrene transformed into sheets.

R-Value: Typically higher R-value, with specific rating variations.

Environmental Impact: Resistant to corrosion, moisture, and rotting.

Form: Mainly used in insulating foam board; versatile for general purposes.

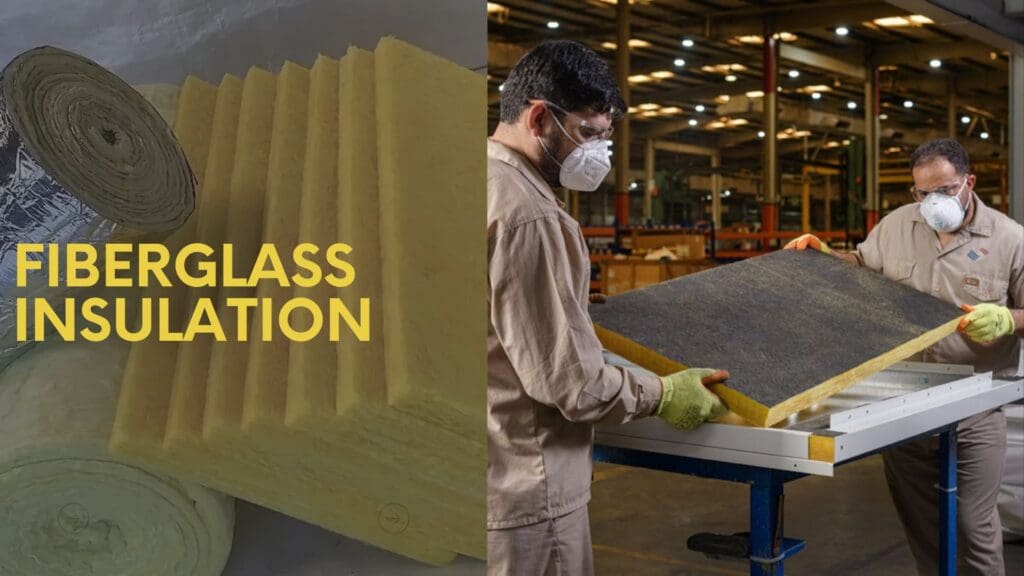

3. Fiberglass Insulation

Fiberglass insulation is a versatile material found in walls, air ducts, floors, and pipes. It comes in loose-fill (blown into spaces) and blanket forms (rolls of varying densities). Made from recycled glass and sand, it’s naturally non-combustible, reducing the risk of fire.

Composition: Made from recycled glass and sand; naturally non-combustible

R-Value: Effective in minimizing heat transfer.

Environmental Impact: Reduces fossil fuel combustion for building heating and cooling

Form: Comes in rolls with varying densities and dimensions.

4. Rock Wool Insulation

Rock wool, made from post-industrial recycled content, is available in loose-fill and blanket forms. It’s highly flame-resistant without additional chemicals. Rock wool, a synthetic material, uses natural minerals, while slag wool is made from blast furnace residue, offering effective insulation properties.

Composition: Around 75% post-industrial recycled content; flame-resistant.

R-Value: Varies with specific product; generally competitive with fiberglass.

Environmental Impact: Considerable use of recycled content; reduced need for additional chemicals.

5. Polyisocyanurate Insulation

Polyiso is a closed-cell foam that provides high R-values for effective thermal insulation. It’s available in liquid, rigid foam board, and spray forms, making it versatile for multiple applications. While installation as in-place foam is often more cost-effective, it may need specific facings to enhance durability.

Composition: Comprises a closed-cell foam formed by a reaction of isocyanate and polyol.

R-Value: Exhibits a high R-value, providing effective thermal insulation.

Environmental Impact: Consideration for environmental impact due to chemical composition.

Form: Available in rigid foam board form, suitable for diverse installations.

Contact Us Today

Ready to discover the benefits of Forma Insulation’s solutions for your business? Contact us to learn more about our polystyrene solutions or to request a custom quote.

From Saudi Arabia

Call Us: +966 54 188 4686

Email: younes.alnadi@formainsulation.com

From Qatar

Call Us: +974 6619 2761

Email:ahmad@forma.qa

Conclusion

These insulation materials are great for keeping your buildings comfortable and energy-efficient in the hot climate. For both homes and commercial buildings, XPS and EPS are excellent choices. They offer strong thermal resistance and are also fire-resistant, making them ideal for the region’s conditions.

When choosing insulation, make sure to check the R-value to ensure you’re getting the right level of thermal protection. It’s always a good idea to consult with experts for the best recommendations based on your location.

FAQ

What insulation material is best for extreme heat?

For the extreme heat in the GCC, XPS (Extruded Polystyrene) and EPS (Expanded Polystyrene) are great choices. Both offer high thermal resistance (R-value), which helps keep indoor temperatures stable, even during the hottest months. They’re also well-suited to the region’s climate.

Are XPS and EPS insulation fire-resistant ?

Yes, XPS and EPS insulation can meet the necessary fire safety standards for building regulations in the GCC when they’re fire-resistant (Class A). These materials are designed to withstand high temperatures, making them safe for residential and commercial buildings.

How long do XPS and EPS insulation materials last in the harsh environment?

XPS and EPS are durable and can last for many years in the harsh climate. These materials are resistant to moisture and high temperatures, ensuring that they maintain their insulating properties over time.

How do XPS and EPS compare to other insulation materials ?

Both XPS and EPS offer excellent energy efficiency. They have higher R-values compared to many other materials, meaning they are more effective at keeping indoor spaces cooler in the summer and warmer in the winter, helping reduce energy consumption.

Where do we use insulation materials?

Insulation serves as the protective layer you can install on your home’s roof, ceiling, external walls, and floor, mitigating the impact of external temperatures on indoor comfort. This results in a reduced need for energy to heat and cool your building, making it more economical to maintain throughout the entire year.