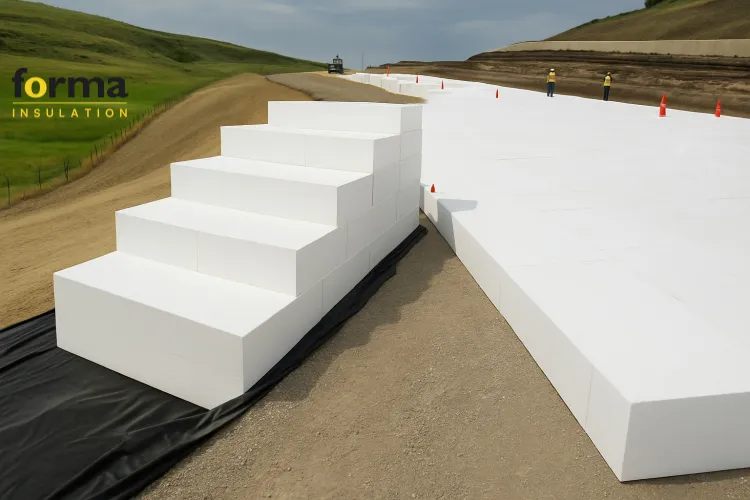

Geofoam is an ultra-lightweight fill material made from expanded polystyrene (EPS). It is manufactured into large blocks that are strong, durable, and easy to install. Unlike traditional soil, gravel, or concrete backfills, EPS geofoam provides a stable, engineered solution for reducing loads on underlying soils and structures.

Because of its lightweight nature—about 1% the weight of soil—contractors and engineers can use geofoam to solve problems in projects where stability, settlement, or weight limitations are major concerns.

At its core, EPS geofoam is a cellular plastic that retains its strength while being lightweight, versatile, and resistant to moisture. This makes it particularly useful in construction, road building, slope stabilisation, and retaining wall applications. Companies like Forma specialise in delivering engineered geofoam solutions to meet modern infrastructure needs.

EPS Geofoam Cost

The cost of EPS geofoam depends on several factors such as block density, size, and project requirements. Although the upfront material investment may be higher than traditional soil or fill, EPS geofoam frequently leads to significant overall savings.

Here’s why EPS geofoam is considered cost-efficient in the long run:

- Reduced Excavation and Transportation – Its lightweight nature makes it easy to handle and transport, lowering logistics expenses.

- Lower Construction Time – Quick installation speeds up project schedules, reducing labour costs and minimising delays.

- Reduced Structural Demands – Since EPS geofoam adds minimal stress to retaining walls, foundations, and embankments, it can reduce the need for additional structural reinforcement.

Contractors and engineers often find that the savings in time, labour, and materials far outweigh the initial investment. Suppliers like Forma provide tailored EPS geofoam solutions that balance cost, performance, and long-term value for different types of projects.

Difference Between Geofoam and Other Lightweight Fill Materials

When engineers consider lightweight fill, they may compare EPS geofoam with alternatives such as lightweight aggregate, cellular concrete, or foamed glass. Each option has its benefits, but geofoam stands out in several ways:

- Weight: EPS geofoam is significantly lighter than lightweight aggregate and soil, making it ideal where ground stability is a concern.

- Installation Speed: Unlike poured concrete or foamed glass, geofoam blocks can be installed immediately without a curing time.

- Load Reduction: Geofoam reduces load stress on foundations and underlying soils more effectively than most alternatives.

- Durability: Geofoam is chemically stable, resistant to freeze-thaw cycles, and does not decompose over time.

For engineers and project owners looking for reliability, EPS geofoam offers a balance of strength, longevity, and cost-efficiency. Forma often recommends geofoam in projects where alternatives would require complex reinforcements or extended construction timelines.

Common Applications of EPS Geofoam

Because of its versatility, EPS geofoam has been adopted in a wide variety of civil engineering and construction applications. Some of the most common include:

- Road Embankments – Geofoam prevents excessive settlement and reduces lateral loads on adjacent structures.

- Retaining Walls – Using EPS geofoam behind walls reduces soil pressure, allowing for thinner and more economical wall designs.

- Slope Stabilisation – Geofoam blocks help stabilise slopes and embankments in landslide-prone areas.

- Foundations – EPS geofoam can be used to reduce loads on weak soils, protecting the integrity of building foundations.

- Sports Fields and Landscapes – Geofoam is often used in stadiums, parks, and landscaping projects where ground shaping and lightweight fill are required.

- Underground Construction – It serves as void fill in tunnels, utility corridors, and pipelines.

With applications spanning infrastructure, transportation, and commercial projects, EPS geofoam is shaping the future of lightweight construction. Leading suppliers like Forma provide customized geofoam solutions for both large-scale infrastructure and private developments.

Read also about: Foam Board Manufacturers

Why EPS Geofoam is the Future of Lightweight Construction

The demand for sustainable, cost-effective, and efficient building materials is growing rapidly. EPS geofoam is positioned to become the go-to material for modern construction because:

- Sustainability: Geofoam is recyclable, and its long lifespan reduces environmental impact.

- Design Flexibility: It can be cut and shaped to meet unique design requirements.

- Performance: Geofoam maintains its structural integrity under heavy loads and diverse weather conditions.

- Reduced Carbon Footprint: Transporting geofoam produces fewer emissions due to its lightweight.

With governments and construction firms worldwide seeking innovative ways to reduce costs and improve efficiency, EPS geofoam is emerging as a preferred choice. Companies like Forma are at the forefront of promoting this shift, offering solutions that enhance project performance while lowering overall construction risks.

Geofoam Suppliers

Choosing the right supplier is critical to ensuring quality and long-term performance. Reliable suppliers like Forma insulation provide certified EPS geofoam products that meet international engineering standards. When selecting a supplier, consider the following factors:

- Product Quality – Ensure the geofoam meets ASTM and ISO standards.

- Customisation – Look for suppliers that can cut and shape blocks to fit project needs.

- Technical Support – A supplier should offer engineering guidance and installation support.

- Delivery Capability – Timely delivery ensures projects stay on schedule.

Forma is recognised for its commitment to quality, timely service, and competitive pricing. Whether it’s for large infrastructure works or smaller commercial projects, Forma ensures that clients receive the best geofoam solutions tailored to their requirements.

Conclusion

EPS geofoam is revolutionising construction by providing a lightweight, durable, and cost-effective alternative to traditional fill materials. From road embankments to slope stabilisation and retaining walls, its versatility is unmatched. With rising demand for efficient construction methods, geofoam is poised to play a central role in future infrastructure projects.

By partnering with trusted suppliers like Forma, contractors and engineers can ensure they are using high-quality geofoam that delivers long-term performance. As the industry continues to evolve, EPS geofoam will remain a cornerstone material for building sustainable, reliable, and innovative infrastructure.

FAQs:

What is EPS geofoam made of?

EPS geofoam is made from expanded polystyrene, a lightweight cellular plastic. It is manufactured into large blocks that are durable, moisture-resistant, and strong enough for construction use.

What are the advantages of EPS geofoam compared to soil or gravel?

EPS geofoam is up to 100 times lighter than soil, reduces settlement, lowers pressure on retaining walls, and speeds up construction. Unlike soil or gravel, it is engineered for predictable performance and long-term stability.

Can EPS geofoam be recycled after use?

Yes. EPS geofoam is fully recyclable. Blocks can be repurposed for new geofoam products or other polystyrene-based applications, contributing to sustainable construction practices.

Read more: EIFS System Cost