EPS (Expanded Polystyrene) sheets are a versatile and popular material used in a variety of applications, from insulation to packaging. If you’re considering using EPS for your next project or product, it’s important to understand its properties, benefits, and how it compares to other materials like PIR (Polyisocyanurate). In this article, we will explore the characteristics of EPS polystyrene sheets, their uses, and how they stack up against other insulation materials. Let’s dive into everything you need to know about EPS polystyrene sheets.

What is an EPS Sheet?

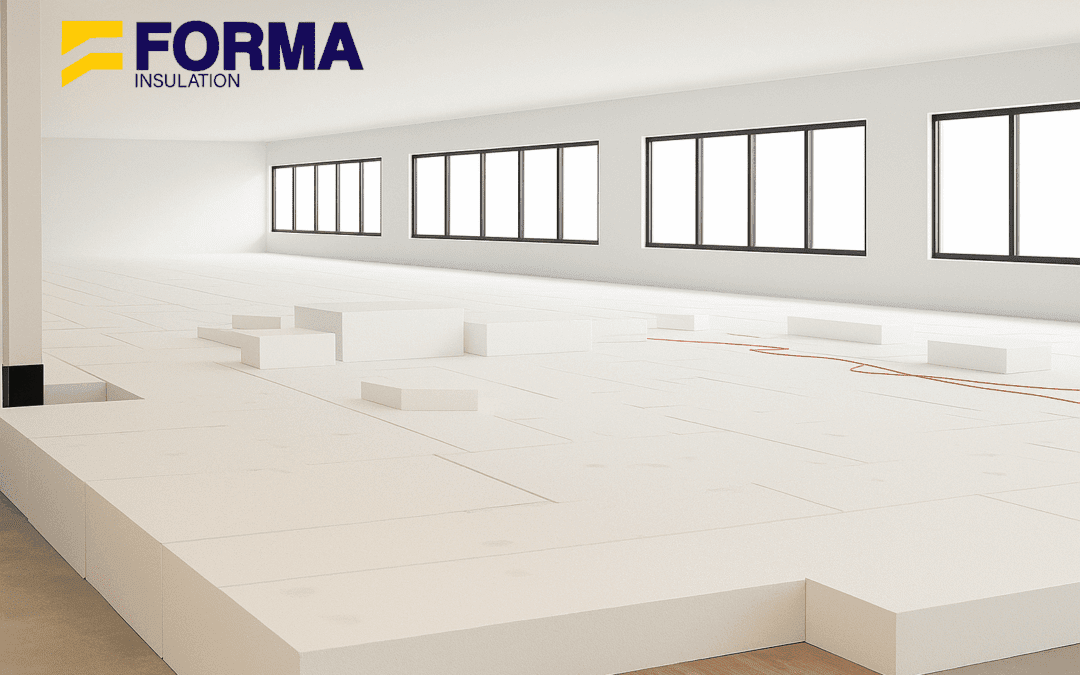

An EPS sheet is a type of expanded polystyrene foam that is lightweight, durable, and offers excellent insulation properties. It is made by expanding polystyrene beads using steam, creating a foam structure with millions of tiny air pockets. These air pockets make EPS sheets highly effective at retaining heat and sound, making them ideal for insulation in construction and packaging. EPS sheets are available in various thicknesses and sizes, including options such as the Polystyrene Board 50mm for more specific applications.

EPS sheets are widely used in building construction, as well as in the packaging industry to protect fragile items during transportation. These sheets are also an eco-friendly choice, as they are recyclable and can be reused in certain applications.

What is the Difference Between EPS and Polystyrene?

While EPS and polystyrene are related, there is a key difference between them. Polystyrene is a type of plastic that exists in two main forms: solid and foam. EPS, or Expanded Polystyrene, is the foam version of polystyrene. The EPS foam is created by expanding polystyrene raw material to beads using steam, resulting in a lightweight, air-filled material that is more insulating than solid polystyrene.

In short, all EPS is polystyrene, but not all polystyrene is EPS. The expanded form (EPS) offers significantly better insulation properties, which is why it is commonly used for thermal insulation and lightweight filling in construction and packaging industries.

Which is Better, PIR or EPS?

When comparing PIR (Polyisocyanurate) and EPS, each material has its unique benefits. PIR is another type of thermal insulation material that is known for its high thermal resistance. It is typically used in high-performance insulation applications due to its superior R-value (thermal resistance) per cm of thickness.

However, EPS polystyrene sheets offer a more affordable and accessible solution, making them a popular choice for both residential and commercial building insulation. While PIR may provide good insulation in specific applications, EPS is more cost-effective, making it a better choice for those looking for high-performance material with value for money without compromising on insulation properties.

For example, if you need thermal insulation boards that offer both high performance and affordability, EPS sheets are a suitable choice. Formainsulation, a trusted name in insulation materials, offers a wide range of EPS products designed to meet various insulation needs.

Expanded Polystyrene Blocks

Expanded polystyrene blocks are large, dense blocks of EPS material that are used in a variety of applications, particularly in construction and Geofoam. These blocks are often used to create insulation panels for walls, roofs, and floors, providing high thermal insulation solutions. They can also be cut into custom sizes and shapes to be utilised in a wide range of lightweight filling applications according to the project requirements.

EPS blocks are lightweight, easy to handle, and cost-effective, making them a popular choice for large-scale construction projects. The blocks can be used in residential and commercial buildings, as well as landscaping projects. They are often chosen for their lightweight nature, high compressive strength, and environmental benefits, as EPS is an eco-friendly material.

Expanded Polystyrene Manufacturers in Saudi Arabia

For businesses, projects and clients in Saudi Arabia looking for high-quality expanded polystyrene sheets, FORMA Insulation is the leading manufacturer in the GCC region. The company produces a wide range of EPS products, including EPS polystyrene sheets for sale, which are used in everything from thermal insulation, Hourdi Blocks, Geofoam applications to packaging.

Formainsulation’s products are known for their quality and durability, meeting the stringent requirements of both the construction and packaging industries. If you’re in Saudi Arabia and need reliable EPS sheets, Formainsulation is a trusted source for your insulation and packaging needs.

EPS Polystyrene Sheets Price

The price of EPS polystyrene sheets can vary depending on factors such as thickness, size, and quantity. Generally, EPS is considered a cost-effective insulation material when compared to other options like PIR. The price of EPS polystyrene sheets is also affected by the desity and the specific properties of the material. For instance, thicker sheets or those with specialized characteristics, such as increased density or enhanced fire resistance, may cost more.

When buying EPS polystyrene sheets, it’s important to consider not just the price, but also the long-term benefits, including energy savings from better insulation and lower heating and cooling costs. Formainsulation offers competitive pricing for its EPS products, making it an affordable option for residential, commercial, and industrial applications.

EPS Polystyrene Sheets Cost

When evaluating the cost of EPS polystyrene sheets, it’s important to recognise their distinct economic advantages over other insulation materials such as PIR. EPS is typically more affordable, offering substantial cost savings without sacrificing quality or performance. This price differential makes EPS an especially attractive choice for large-scale construction projects and budget-conscious developments.

What sets EPS apart is not only its cost-effectiveness but also its efficient thermal insulation and high compressive strength properties. Despite being more affordable, EPS maintains its ability to significantly enhance energy efficiency, reduce heating and cooling costs, and provide excellent thermal insulation. These qualities ensure that EPS is a wise investment for both new builds and renovation projects using EIFS External Insulation Finishing System aiming to optimise cost while still meeting thermal insulation performance requirements.

For those seeking a balance of high-quality insulation at a competitive price, FORMA Insulation, a prominent supplier of EPS polystyrene sheets and Blocks, offers an extensive selection of products that combine durability with affordability. Their strategy ensures that customers receive the best value for their investment, allowing them to make informed decisions.

Conclusion

EPS polystyrene sheets are an excellent choice for anyone looking for affordable, durable, and effective insulation. Whether you’re insulating a home, office, or industrial facility, EPS provides reliable thermal and sound insulation properties that make it a top choice for a wide range of applications.

When considering the best material for your project, it’s important to weigh the advantages of EPS against other options like PIR. While PIR offers higher performance in some areas, EPS is more cost-effective and still provides excellent insulation, making it ideal for most applications.

For those in Saudi Arabia, Formainsulation is a trusted name in EPS manufacturing, offering a wide range of EPS polystyrene sheets for sale at competitive prices. If you’re looking for a reliable and affordable insulation solution, Formainsulation’s EPS products are a great choice.

With its many advantages, including cost-effectiveness, versatility, and environmental friendliness, EPS polystyrene sheets are sure to continue being a popular choice in the insulation industry.

1. What are the benefits of using EPS polystyrene sheets for insulation?

EPS polystyrene sheets provide excellent thermal and sound insulation, are lightweight, cost-effective, and environmentally friendly. They help maintain energy efficiency by reducing heat transfer, making them ideal for both residential and commercial projects.

2. How do EPS polystyrene sheets compare to other insulation materials like PIR?

EPS is more affordable than PIR while still offering high thermal insulation. Although PIR provides a good R-value, EPS remains a popular choice due to its excellent performance at a lower cost.

Read more about: Polystyrene Foam