When it comes to construction, signage, insulation, or even surfboard shaping, foam boards play a vital role. With a wide variety of applications and material types, finding the right foam board manufacturers can significantly impact the quality, durability, and performance of your end product. Whether you’re sourcing foam boards for commercial use or personal projects, understanding the options available in the market is essential.

PVC Foam Board in Saudi Arabia

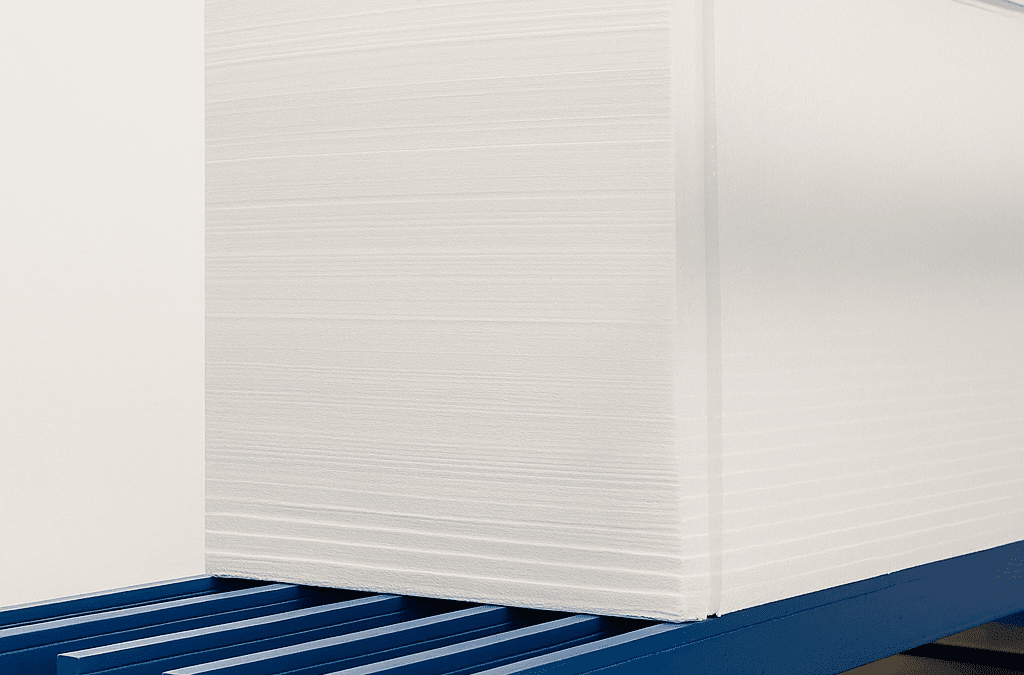

PVC foam boards are widely used in Saudi Arabia across industries such as construction, interior design, advertising, and furniture manufacturing. Known for their lightweight nature and strong surface durability, PVC foam boards resist moisture, flames, and chemicals, making them ideal for both indoor and outdoor applications.

These boards are easy to cut and fabricate, making them popular for:

- Interior wall cladding

- Kitchen cabinets and bathroom vanities

- Digital printing and signage

- False ceilings and partitions

With increasing demand, local foam board manufacturers in Saudi Arabia now produce PVC foam boards in various thicknesses, densities, and finishes to suit market needs.

Different Types of Foam Boards and Their Uses

Foam boards are manufactured using various polymers and processes, and each type has its distinct advantages:

1. PVC Foam Board

As mentioned above, PVC foam boards are strong, waterproof, and fire-retardant, making them suitable for architectural applications, displays, and signage.

2. Polystyrene Foam Board (EPS and XPS)

Polystyrene boards are known for their thermal insulation properties. Expanded polystyrene (EPS) is lightweight and cost-effective, while extruded polystyrene (XPS) offers greater moisture resistance and compressive strength. These are commonly used in:

- Roof and wall insulation

- Cold storage rooms

- Packaging materials

3. Polyurethane Foam Board

These boards have higher insulating value per inch compared to EPS or XPS. Polyurethane foam boards are often used in industrial insulation systems where space is limited.

4. High-Density Foam Board

These rigid boards are used in applications requiring structural support, such as model making, boat building, and structural panels.

5. Foam Board for Crafts and Visual Projects

Lightweight foam core boards made of polystyrene with a paper or plastic exterior are widely used in the arts, schools, and exhibition displays.

Understanding these types helps in selecting the appropriate material based on use case, environmental conditions, and durability expectations.

Read more details about: Foam Board

Local vs. Imported Foam Boards: Which Is Better for Your Business?

The decision between using locally manufactured foam boards and importing them can impact cost, lead times, and compliance. Here’s what to consider:

Local Foam Boards

- Faster delivery and lower shipping costs

- Easier communication and after-sales support

- Adherence to regional standards and building codes

Imported Foam Boards

- May offer access to specialized or high-performance grades

- Available from global brands with long-standing reputations

- Can fill gaps in supply during local shortages

Ultimately, partnering with established foam board manufacturers in your region ensures better project coordination, while imported products may be suitable for niche applications.

Read more about: Foam Sheeting

Foam Board at Home Depot and Similar Retailers

While large-scale projects often require bulk sourcing from manufacturers, individuals and small businesses frequently buy foam boards from hardware chains like Home Depot. These stores usually stock general-purpose foam boards such as:

- Insulation sheets

- Display boards

- Craft foam boards

These boards are convenient for DIYers, hobbyists, and smaller commercial operations. However, for larger volumes, custom sizes, or project-specific materials, working directly with foam board manufacturers or local distributors offers greater flexibility and cost-efficiency.

Why Working with Certified Foam Board Manufacturers Matters

Certification ensures that the foam boards meet performance and safety standards set by regulatory authorities. Certified foam board manufacturers provide:

- Quality assurance: Verified thermal, mechanical, and fire resistance properties

- Compliance: Meets local and international building codes

- Reliability: Consistent supply and standardized products

For sectors like construction and insulation, where performance directly affects building safety and energy efficiency, certification is non-negotiable.

Moreover, manufacturers with ISO, ASTM, or CE certifications often have in-house testing facilities, R&D capabilities, and offer technical support to engineers, architects, and project managers.

Foam Board Surfboard Blanks

One niche yet growing application is the use of foam boards in surfboard manufacturing. Polyurethane and EPS foam boards are shaped into blanks, then laminated with fiberglass and resin to create strong, lightweight surfboards.

- EPS foam is lightweight, eco-friendlier, and compatible with epoxy resins

- PU foam has a smoother finish and is easier to shape manually

Professional shapers and hobbyists often source foam blanks directly from foam board manufacturers specializing in surf and marine foam products.

Foam Board Insulation

Foam board insulation is a popular solution for thermal protection in buildings. It is widely used in:

- Exterior wall insulation (EIFS systems)

- Roof insulation under concrete or metal decking

- Basement and crawl space insulation

- Cold storage and HVAC ducting

XPS and Polyiso foam boards are preferred in high-moisture areas due to their closed-cell structure. Foam board insulation provides high R-values with minimal thickness, saving space and improving energy efficiency.

Local foam board manufacturers in Saudi Arabia and the GCC, such as Formainsulation, are increasing production of thermal insulation boards to meet the region’s energy-saving initiatives and green building requirements.

Conclusion

Choosing the right foam board manufacturer is critical, whether your focus is on construction insulation, signage, surfboards, or custom applications. From PVC foam boards in Saudi Arabia to surfboard blanks and structural insulation, foam boards are integral to many industries.

Partnering with certified and experienced manufacturers ensures access to quality products, technical expertise, and responsive service. Local production offers the benefit of quick delivery and support, while imported products may cater to specialized requirements.

As demand grows, especially in the Middle East, reliable suppliers and manufacturers will continue to play a central role in delivering sustainable and innovative foam solutions for both commercial and personal use.

1. What are the most common types of foam boards used in Saudi Arabia?

In Saudi Arabia, the most common types of foam boards include PVC foam boards, polystyrene boards (EPS and XPS), and polyurethane boards. Each type is chosen based on its specific application, whether for construction, signage, insulation, or surfboard cores.

2. Why should I choose certified foam board manufacturers?

Certified foam board manufacturers ensure consistent product quality, compliance with local building standards, and reliable customer support. Working with certified suppliers also reduces project risk and ensures long-term performance.

Read more about: Insulation Company