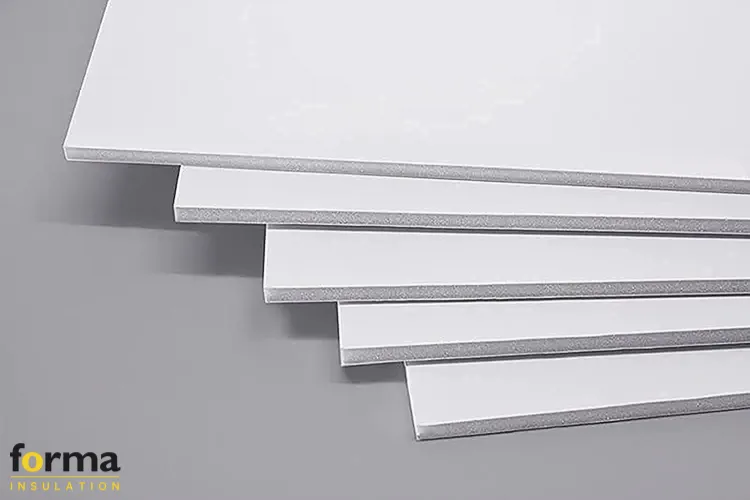

Foam sheeting is a lightweight, versatile material made from expanded or extruded plastic polymers such as polyethylene, polystyrene, or polyurethane. Its unique combination of flexibility, cushioning, and ease of use has made it an essential material across numerous industries. From packaging fragile electronics to insulating buildings, foam sheeting’s adaptability makes it a go-to choice for professionals and hobbyists alike.

Available in a wide range of thicknesses, densities, and colors, foam board sheet offers solutions for applications that require protection, insulation, or creative expression. Its cost-efficiency and practical properties allow foam sheeting to serve both industrial-scale uses and DIY projects effectively. This article explores the characteristics, types, applications, and purchasing considerations related to foam board sheet.

PVC Foam Board in Saudi Arabia

One popular variant of foam board sheet is the PVC foam board, widely used in Saudi Arabia for construction, advertising, and interior decoration. PVC foam boards combine the lightweight, cushioning benefits of foam sheeting with the rigidity and durability of PVC plastic, making them excellent for signage, wall panels, and exhibition displays.

In Saudi Arabia, PVC foam boards are readily available through various suppliers offering both domestic and imported products. Businesses often prefer local PVC foam boards for cost-effectiveness and faster delivery, while imported boards may offer superior finish or specialized properties. Whether for commercial advertising or architectural use, PVC foam boards represent an important segment of the ffoam board sheet market in the region.

Different Types of Foam Boards and Their Uses

IIt’s important to distinguish between foam sheeting and foam boards, as they serve different purposes though both come from foam materials:

- Foam Sheet: This type is usually thin, flexible, and sold in rolls or flat sheets. It is perfect for cushioning, packaging, lining drawers, and wrapping fragile items due to its shock-absorbing qualities.

- Foam Board: Foam boards are thicker, rigid sheets commonly used in signage, art mounting, presentations, and architectural modeling. They provide structural support while remaining lightweight.

Types of foam boards vary by material composition (PVC, polystyrene, polyurethane), density, and thickness. Each type suits specific applications, such as insulation in construction or display purposes in retail environments. Understanding the differences allows users to select the right foam product for their projects.

Read more details about: Thermal Insulation Boards

Local vs. Imported Foam Boards: Which Is Better for Your Business?

When sourcing foam sheeting or foam boards, businesses in Saudi Arabia often weigh the benefits of local versus imported materials:

- Local Foam Boards and Sheets: Typically more cost-effective, with faster shipping and the ability to customize orders quickly. Local manufacturers can offer tailored customer service and support, helping businesses meet urgent or specific requirements.

- Imported Foam Boards and Sheets: Often provide normal quality finishes or specialized materials not produced locally. These may come with certifications to meet specific standards, which are crucial for certain industries.

For most commercial and construction purposes, locally sourced foam sheets offer excellent value. However, for high-end applications like signage, some imported foam boards can be worthwhile despite their higher costs.

Foam Board at Home Depot

In international markets such as the United States, retailers like Home Depot provide extensive selections of foam boards and foam board sheet. Home Depot stocks foam boards in popular sizes and thicknesses, catering to construction, crafting, and signage needs.

While Home Depot is not available in Saudi Arabia, similar foam sheets and foam board products are available at local stores such as Jarir Bookstore or through specialty suppliers, helping to meet demand. For customers seeking large quantities of foam boards for commercial use, FORMA Insulation offers high-quality products that cater to a wide range of requirements.

Why Working with Certified Foam Board Manufacturers Matters

Choosing foam board sheet or foam boards from certified manufacturers guarantees product consistency, safety, and compliance with industry standards. Certified producers maintain quality controls on density, thickness, fire resistance, and environmental impact—factors that directly affect product performance and longevity.

Certified foam sheet is essential for applications such as:

- Construction insulation, where thermal resistance and fire safety matter

- Packaging delicate electronics requiring anti-static foam sheets

- Medical padding where hygiene and biocompatibility are critical

Working with trusted manufacturers also ensures access to technical support, customization options, and reliable delivery schedules, which are vital for businesses relying on foam sheets for their operations.

Read also about: xps insulation foam

Foam Board for Surfboards

Foam boards specifically designed for surfboards highlight another specialized use of foam sheetس. These foam cores provide lightweight buoyancy and structural support, while being easily shaped and coated with fiberglass or epoxy resin.

Surfboard foam boards differ from typical packaging or signage foam sheets in their density and resilience. The foam must withstand repeated water exposure and impacts while maintaining its form. Manufacturers produce surfboard foam boards tailored to different surfing styles and conditions, making foam sheets an integral material in the water sports industry.

Foam Board Insulation

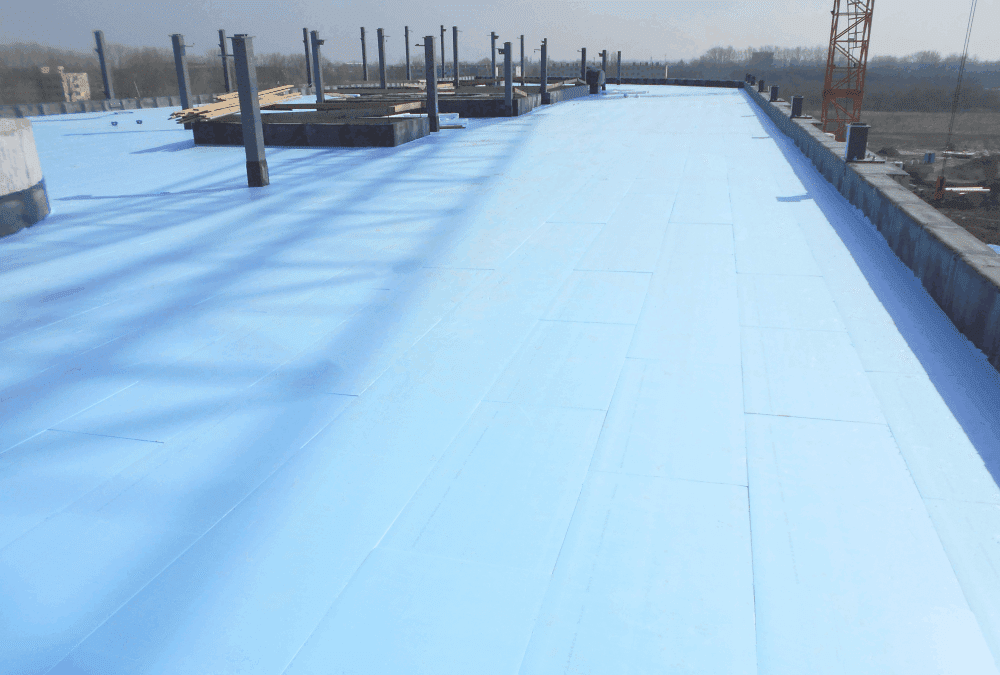

One of the most widespread uses of foam sheets is in foam board insulation. This application leverages foam sheet’s thermal insulating properties to improve energy efficiency in buildings. Foam board insulation is often made from polystyrene or polyurethane foam sheeting, offering high R-values per inch of thickness.

In construction, foam sheets insulation is installed in walls, roofs, and foundations to reduce heat transfer, moisture buildup, and sound transmission. Its lightweight nature makes it easy to handle and install, while its durability extends building lifespan and performance. Formainsulation provides high-quality foam sheeting solutions designed to meet modern building standards, ensuring excellent thermal efficiency and long-term reliability.

Conclusion

Foam sheet is a remarkably versatile material with applications spanning packaging, construction, crafts, automotive, and beyond. Its range of materials, densities, and thicknesses allows it to meet diverse needs—from delicate cushioning to durable insulation.

In Saudi Arabia, foam sheets is accessible through local and imported sources, including PVC foam boards widely used for signage and interior design. Understanding the differences between foam sheeting and foam boards, as well as selecting certified manufacturers, helps businesses and consumers achieve the best results.

Whether for industrial use or creative projects, foam sheeting’s combination of flexibility, protection, and affordability makes it an indispensable material. By choosing the right type, thickness, and supplier, users can fully harness the benefits of foam sheets for their specific applications.

Common Questions

What materials are used to make foam sheeting?

foam sheets is commonly made from plastic polymers such as polyethylene, polystyrene, or polyurethane, each offering different properties for various applications.

What are the main uses of foam sheeting?

foam sheets is used in packaging, insulation, construction, crafts, automotive cushioning, and even medical padding.

Read more about: