Introduction

In Saudi Arabia’s hot climate, energy efficiency is crucial, and proper insulation plays a pivotal role in reducing cooling costs.insulate block walls doesn’t have to break the bank. Affordable insulation solutions, such as Expanded Polystyrene (EPS), provide excellent thermal resistance while keeping expenses low. In this guide, we’ll explore cost-effective ways to insulate block walls and why these methods are ideal for the Saudi construction industry.

Table of Contents

What Are Cheap Insulation Methods for Block Walls?

Block walls are a common choice in construction, but their thermal conductivity can lead to energy inefficiency if not insulated properly. Insulating these walls enhances energy savings, reduces environmental impact, and improves indoor comfort.

Methods to Insulate Block Walls Using EPS

a. Applying EPS Sheets on Block Walls

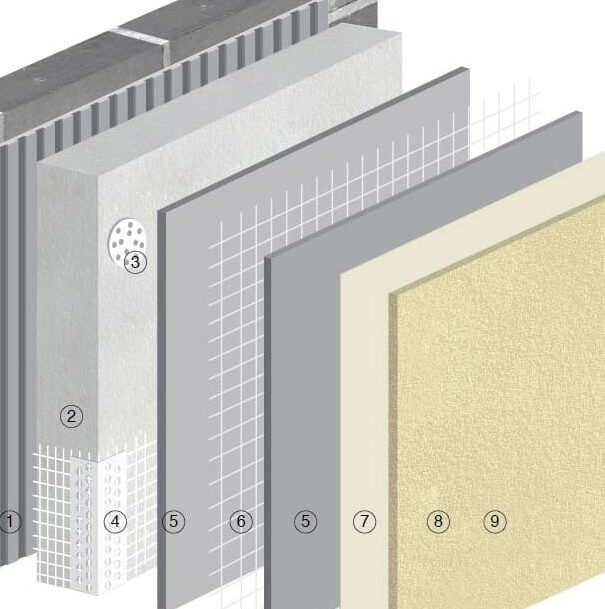

EPS sheets are rigid foam boards that are typically used as continuous insulation on the surface of block walls. They come in various thicknesses and are often used to insulate both the exterior and interior of walls.

- Usage: EPS sheets are generally applied as a large, continuous layer over the block wall. They are adhered to the wall with an adhesive, and in some cases, they may be covered with an additional layer of plaster, stucco, or siding on the exterior.

- Purpose: The primary goal is to provide thermal insulation. EPS sheets can reduce heat loss or gain through the wall, improving the overall energy efficiency of the building.

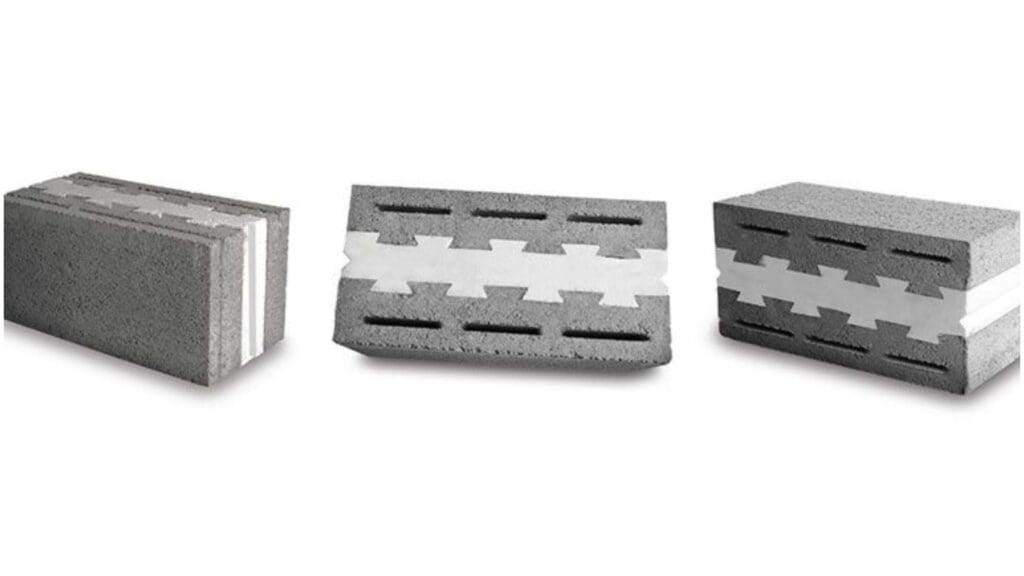

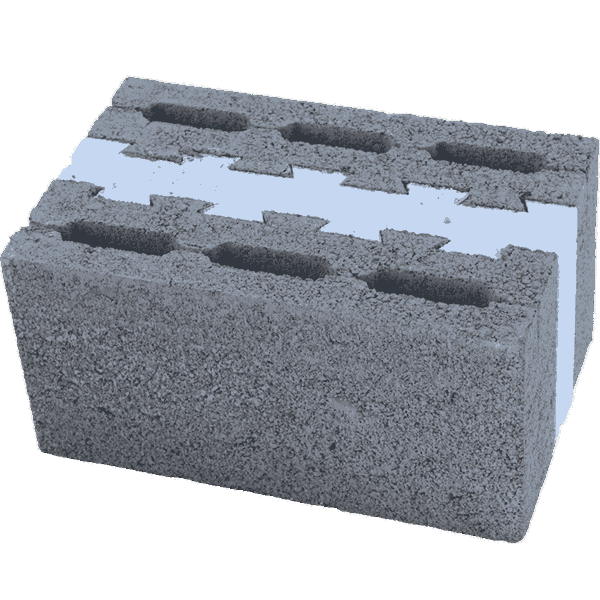

b. Using EPS Inserts in Thermal Blocks

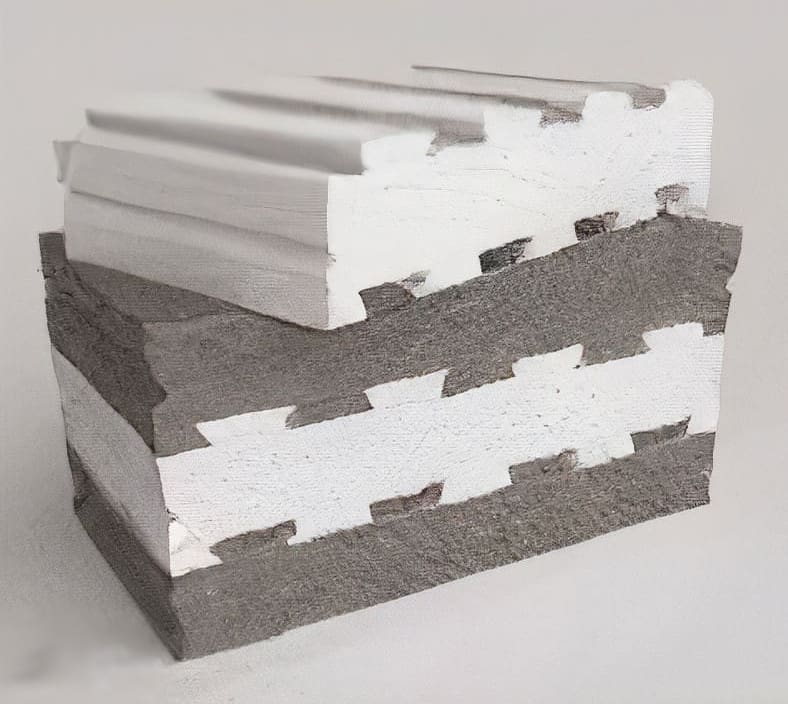

EPS inserts are small, pre-formed pieces of EPS foam that fit into the cavities of concrete or block walls, typically during the construction process. They are used as an integrated part of the wall assembly rather than a surface insulation.

- Usage: EPS inserts are placed into the cavities of block walls, such as in hollow concrete block systems (CMU – Concrete Masonry Units). They help to reduce thermal bridging between the blocks, improving the overall insulation of the wall. These inserts are often used in insulated block construction (ICF) or to fill voids in hollow blocks to increase the thermal resistance of the wall.

- Purpose: The purpose of EPS inserts is to enhance the insulation properties of the block wall by filling air gaps and reducing heat flow through the blocks, especially when these blocks are hollow or have large voids.

Benefits of EPS Insulation for Block Walls in Saudi Arabia

When it comes to insulating block walls, both EPS Sheets and EPS Inserts offer unique advantages that cater to different construction requirements. Here’s a comparison of their benefits:

Benefits of EPS Sheets for Block Walls

EPS sheets are a popular choice for surface insulation due to their versatility and efficiency:

- Continuous insulation with fewer gaps or seams.

- High R-value per inch of thickness, providing effective thermal resistance.

- Moisture-resistant and lightweight.

- Simple and fast to install.

- Can be used both inside and outside of the building, depending on the application.

- Common applications: Used for insulating the exterior of masonry or concrete block walls (e.g., in EIFS – Exterior Insulation and Finish Systems) or on the interior walls of basements.

Benefits of EPS Inserts in Thermal Blocks

EPS inserts are ideal for internal insulation within block wall systems, addressing thermal bridging and enhancing energy efficiency:

- Increases the R-value of a block wall by filling the cavities with EPS foam.

- Reduces the effect of thermal bridging, where the concrete blocks conduct heat more readily than the insulation material.

- Can contribute to improving soundproofing as well as thermal insulation.

- Often used in conjunction with other building materials, such as air barriers or vapor barriers.

Both EPS Sheets and EPS Inserts provide effective, sustainable insulation solutions, making them ideal for Saudi Arabia’s energy-efficient construction projects.

Common Applications of Insulated Block Walls in Construction Projects

Insulated block walls offer versatile solutions for various construction scenarios. Depending on the insulation method—EPS Sheets or EPS Inserts—the applications differ in approach and functionality. Here’s a breakdown:

1. EPS Sheets

EPS sheets are highly effective for providing thermal insulation on the external or internal surfaces of block walls. These are commonly used in:

- Exterior Insulation and Finish Systems (EIFS): EPS sheets are applied on the outer surface of masonry or concrete block walls to create a seamless, insulated barrier. This method enhances the building’s energy efficiency while allowing for aesthetic finishes.

- Interior Wall Insulation: Ideal for insulating basement walls, where energy efficiency and moisture resistance are critical. EPS sheets can be glued or mechanically attached to create a protective thermal layer.

2. EPS Inserts

EPS inserts are designed to be integrated directly within the structure of block walls, filling cavities and providing internal insulation. These are typically used in:

- Hollow Block Systems: Inserts are placed within the voids of hollow blocks during construction to reduce thermal bridging and improve overall insulation.

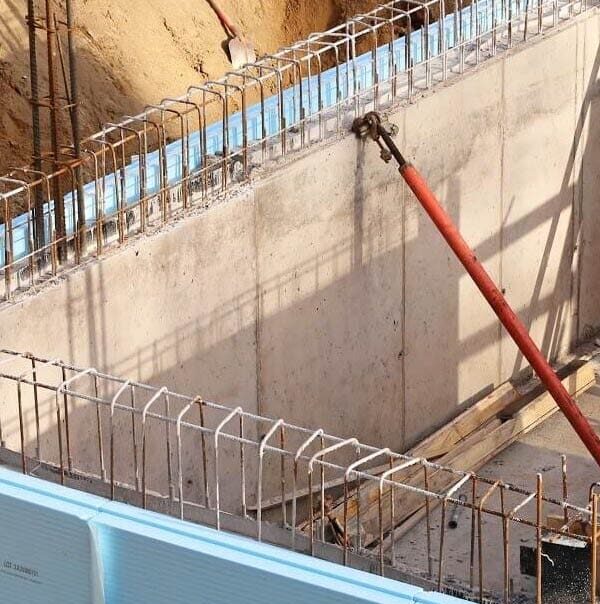

- Insulated Concrete Forms (ICF): EPS inserts are integrated into concrete forms, enhancing the thermal performance of precast or poured concrete walls.

- Precast Concrete Walls: Inserts provide consistent insulation throughout the structure, ensuring energy efficiency and reduced heat transfer.

Both methods cater to specific construction needs, contributing to energy efficiency, cost savings, and enhanced durability in residential, commercial, and industrial projects.

Key Considerations When Choosing Insulation for Block Walls

- Thermal Resistance (R-Value)

Higher R-values indicate better insulation performance. Choose materials suited for Saudi Arabia’s climate. - Installation Cost

Compare upfront costs and long-term savings to identify the most economical option. - Moisture Resistance

Opt for materials that resist humidity and prevent mold growth, such as EPS or spray foam. - Fire Safety

Ensure that the insulation complies with fire safety regulations in Saudi Arabia. - Environmental Impact

Choose sustainable materials to support eco-friendly construction practices.

Conclusion

Proper insulation for block walls doesn’t have to strain your budget. Cost-effective options like EPS sheets and EPS inserts provide excellent thermal performance while meeting the energy efficiency demands of Saudi Arabia’s climate. By choosing EPS as an insulation solution, you can lower cooling costs, enhance comfort, and contribute to sustainable construction.

Ready to insulate your block walls affordably? Explore our cost-effective insulation products or contact us today for expert advice tailored to your project needs.

FAQ

What is the best insulation material for block walls in Saudi Arabia?

EPS (Expanded Polystyrene) and spray foam are among the best options due to their affordability, thermal efficiency, and durability in hot climates.

How much does it cost to insulate block walls in Saudi Arabia?

The cost depends on the material used and the wall’s surface area. EPS sheets are generally the most cost-effective.

Can block wall insulation reduce cooling costs in Saudi homes?

Yes, insulating block walls significantly reduces heat transfer, lowering cooling costs by up to 30% in most Saudi homes.

Is EPS insulation safe for residential buildings?

Yes, EPS insulation is safe and widely used in Saudi Arabia. It meets fire safety standards and is resistant to moisture and pests.

How long does it take to install insulation for block walls?

Installation time depends on the chosen method. EPS panels or reflective foil can be installed within a few days for an average-sized building.

Can insulation materials be recycled in Saudi Arabia?

Yes, materials like EPS are recyclable, aligning with the sustainability goals of Saudi Arabia’s Vision 2030.