Introduction

When it comes to choosing between Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS) for insulation, the difference isn’t just technical—it affects your building’s energy efficiency, moisture resistance, and cost. Whether you’re in Saudi Arabia, Qatar, or anywhere in the GCC, understanding the XPS vs EPS debate is critical for making the right choice for your project.

Table of Contents

What’s the Real Difference Between EPS and XPS?

EPS insulation is made by expanding tiny beads of polystyrene, making it a lighter, more flexible option. On the other hand, XPS foam is created through an extrusion process that results in a denser, stronger, and less permeable material. Both offer solid insulation, but which one should you choose?

XPS vs EPS R-Value: What You Need to Know

When it comes to thermal performance, the R-value is your main concern. The higher the R-value, the better the material performs in terms of insulation.

- EPS R-value: Around 4 per inch. It provides steady performance over time and works well in general insulation tasks like walls, roofs, and attics.

- XPS R-value: Slightly better at 5 per inch. This means XPS foam gives a bit more thermal resistance, which can be a deciding factor when you’re looking at high-performance insulation.

But, don’t forget that the XPS R-value can drop over time, especially if exposed to moisture. So while it starts strong, it may not hold up in the long run like EPS does.

Moisture Resistance: XPS vs EPS Under Slab

For areas that are exposed to moisture, like under slabs or foundations, XPS has the clear edge. Its closed-cell structure keeps water from seeping in, making it more suitable for wet environments. EPS foam, while still decent, doesn’t hold up as well under constant moisture.

If you’re working on a project where moisture resistance is crucial, the answer is clear—XPS is your go-to.

The Price Factor: EPS vs XPS Cost

One of the biggest deciding factors between XPS vs EPS insulation is cost.

- EPS is generally cheaper than XPS. So if you’re looking to insulate a large area on a budget, EPS foam board might be the way to go. It’s still highly effective for general insulation and offers solid R-value at a fraction of the cost.

- XPS is more expensive upfront, but it offers better moisture resistance, compressive strength, and durability in demanding applications.

Not sure which one fits your project? At Forma Insulation, we’ve got the expertise to guide you in choosing the right insulation materials, no matter your needs. Whether it’s for a high-performance building, a budget-friendly project, or one that requires maximum durability, we’re here to help.

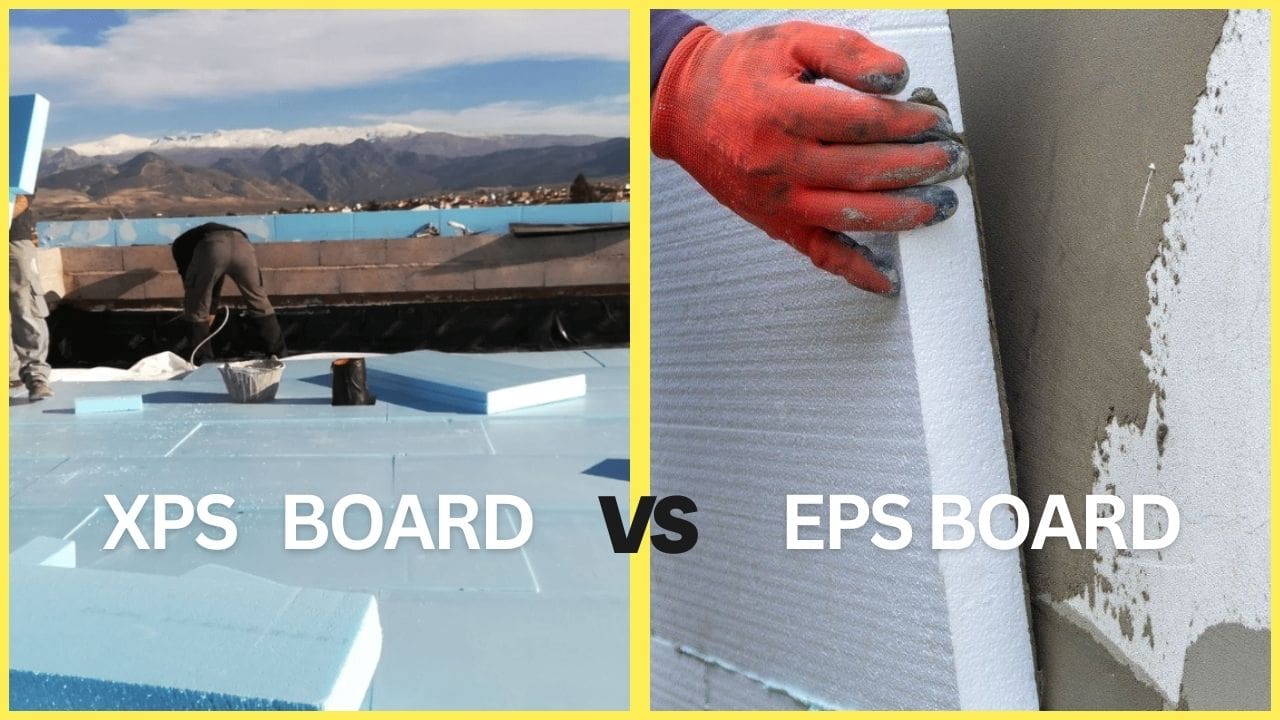

XPS vs EPS Insulation Board: Which to Use?

When choosing between XPS vs EPS foam board, you need to consider the application. EPS foam is versatile, easy to cut, and works great for standard insulation needs. However, if you need more strength or moisture resistance, XPS insulation board will give you more reliable performance in the long term.

If you’re insulating in areas like basements, foundations, or wet environments, XPS should be your choice. If the project is more about cost efficiency and you don’t need the extra durability, EPS foam will get the job done.

Which is Better: EPS or XPS?

This boils down to what’s more important for your project: cost, strength, or moisture resistance?

- For a tight budget: EPS wins. It’s affordable, offers good thermal resistance, and works well in general insulation applications.

- For superior moisture resistance: XPS is your material. It’s built for areas that deal with moisture, like under-slab insulation or foundations.

- For strength: If your insulation needs extra support, like in heavy-duty applications, XPS foam is more durable.

Conclusion

In the GCC, the choice between XPS and EPS depends on your specific needs. EPS is cost-effective and works well in dry climates for general insulation, while XPS offers the strength and moisture resistance needed for harsher environments.

Let’s talk about your next insulation project. Contact us and make sure you’re getting the best for your investment. We’re committed to providing top-quality materials and expert advice to ensure your project stands the test of time.

FAQ

1. Which one is better for my project—XPS or EPS?

If you’re looking for superior moisture resistance, durability, and thermal performance, XPS is your go-to, especially for places like under slabs or exterior walls. But if cost is a bigger factor and your project isn’t under constant moisture exposure, EPS is an affordable alternative that still delivers good insulation for most standard uses.

2. Can EPS be used under a slab?

Yes, EPS can definitely be used under slabs, but it’s important to note it’s less moisture-resistant than XPS. If you’re working in a high-moisture environment, XPS would be a better choice, as it will hold up longer without degrading. EPS is fine in drier climates or projects where moisture isn’t a big issue.

3. Is XPS more durable than EPS?

Absolutely, XPS is more durable. It has a higher compressive strength, which means it can handle more weight without breaking down. This makes XPS better for structural applications, like beneath heavy loads or in areas with high foot traffic. EPS is more fragile, but it still performs well in low-stress situations.

4. Which material is more environmentally friendly, XPS or EPS?

EPS is generally considered the greener option because it can be made from recycled materials and is fully recyclable. XPS, however, often contains HFCs (hydrofluorocarbons) that aren’t as eco-friendly. So, if sustainability is a priority, EPS is the better choice.

5. How do XPS and EPS perform when it comes to fire resistance?

Both XPS and EPS used in Forma Insulation products are fire-resistant. While XPS generally has better fire resistance due to its fire-retardant additives, EPS can also be made with similar fire-resistant treatments. Fire safety is a top priority, and we ensure that our insulation materials are up to the task.