Introduction

Polystyrene foam is one of the most widely used materials across various industries, from food packaging to construction. Known for its exceptional insulation properties, lightweight nature, and cost-effectiveness, polystyrene foam is crucial for many applications in the UAE, Qatar, Saudi Arabia, and the wider GCC region. This article explores the different types of polystyrene, their properties, and the industries where they make a significant impact.

Table of Contents

Types of Polystyrene Foam

Polystyrene foam is manufactured by adding blowing agents that create a structure that is 95-98% air, giving it excellent thermal insulation properties. Due to its low thermal conductivity, polystyrene foam is widely used in packaging, construction, and automotive industries across the GCC.

Expanded Polystyrene (EPS) Foam

EPS foam, a type of polystyrene foam, is made by the suspension polymerization of styrene monomer followed by the introduction of blowing agents. It is a closed-cell foam that is primarily white and lightweight.

Properties of Expanded Polystyrene (EPS)

- Lightweight and Rigid

- Low Thermal Conductivity

- Low Moisture Absorption

- Excellent Dimensional Stability

- High Compressive Strength

EPS Applications in GCC

EPS is used in various industries across GCC countries, such as packaging, food storage, construction, and automotive:

- Food Packaging: EPS foam maintains the freshness of food products by offering excellent insulation properties, particularly in food service containers and disposable packaging.

- Industrial Packaging: Its excellent cushioning properties make EPS the ideal material for packaging delicate items such as electronics and medical components.

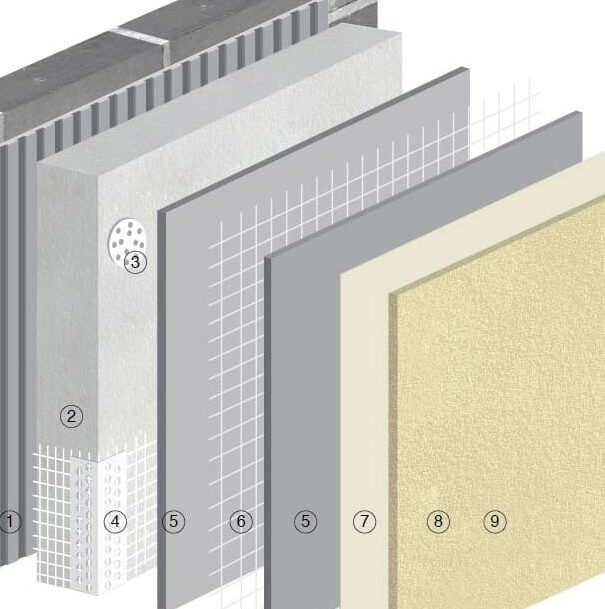

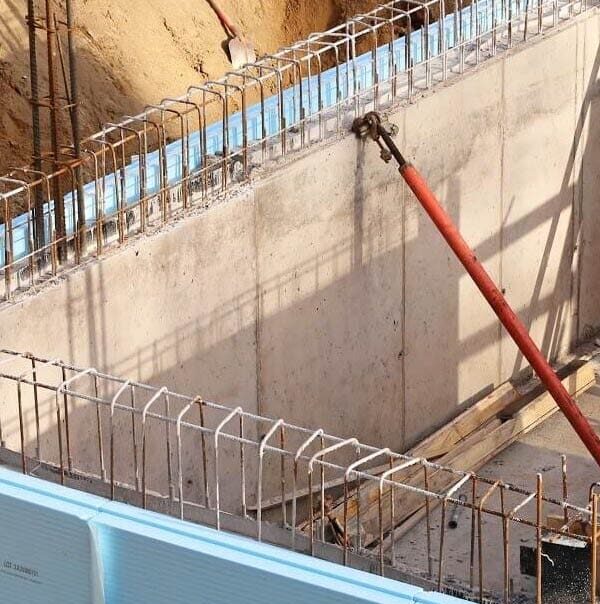

- Construction: EPS is commonly used in insulated concrete forms (ICF), structural insulated panels (SIP), and for roofing, flooring, and walls in buildings across the UAE, Saudi Arabia, and Qatar.

- Marine Applications: EPS foam is a key material in marine applications, such as floating docks, pontoon boats, and rafts, due to its superior buoyancy, lightweight nature, and resistance to water damage. It ensures long-lasting performance in saltwater environments across the GCC.

Extruded Polystyrene (XPS) Foam

XPS foam is another popular polystyrene foam variant, made through a continuous extrusion process, which results in a closed-cell foam that is denser and stronger than EPS.

Properties of XPS Foam

- More Resistant to Moisture and Water Vapor

- Higher Compressive Strength

- Improved Surface Roughness

- Excellent Thermal Insulation

- High Durability

XPS Applications in GCC

XPS foam is widely used for thermal insulation in buildings, as well as cold storage solutions. It is also increasingly popular in construction for roofs, walls, and floors, ensuring energy-efficient buildings throughout the GCC.

Why Choose Polystyrene Foam for Your Projects?

Polystyrene foam is an indispensable material in many GCC industries due to its cost-effectiveness and range of beneficial properties, including:

- Thermal Insulation: Ideal for food packaging and construction.

- Lightweight: Makes handling and transportation easier, especially in automotive and packaging applications.

- Durability: Provides shock absorption and impact resistance in various industrial applications.

- Sustainability: While not biodegradable, polystyrene foam can be recycled, contributing to more sustainable practices in the GCC region.

Get the Best Polystyrene Foam Solutions in GCC Countries

Whether you need expanded polystyrene (EPS) or extruded polystyrene (XPS) for construction, food packaging, or industrial applications, Forma Insulation offers top-quality polystyrene foam products that meet the highest standards. Our products provide unparalleled insulation, cushioning, and protection.

Contact us today to get the best polystyrene foam solutions in the UAE, Qatar, Saudi Arabia, and the GCC!

Conclusion

Polystyrene foam plays a crucial role across many sectors in GCC countries, offering an ideal balance of strength, insulation, and cost-effectiveness. With a wide range of applications, from food packaging to construction, it is clear why polystyrene foam remains a leading choice for industries across the region.

Request a Quote or call us to learn more about how polystyrene foam can benefit your business!

FAQ

Who is the largest manufacturer of EPS foam in the GCC?

Forma Insulation is a leading manufacturer of EPS foam in the GCC, trusted for its high-quality products that cater to marine, construction, and insulation needs across Saudi Arabia, Qatar, and the region.

Is polystyrene foam the same as EPS foam?

Yes, EPS (Expanded Polystyrene) foam is a type of polystyrene foam. It is lightweight, durable, and widely used for insulation, packaging, and marine applications like pontoons.

How to cut polystyrene foam?

Polystyrene foam can be easily cut using a hot wire cutter, craft knife, or specialized foam cutting tools. Always ensure precise measurements and work in a well-ventilated area for best results.

What is the difference between polystyrene foam and Styrofoam?

Polystyrene foam refers to materials made from styrene monomers, while Styrofoam is a branded type of expanded polystyrene foam commonly used for insulation and packaging. Both are durable and lightweight, but Styrofoam is often associated with specific applications.