Introduction

In construction, innovation drives efficiency—and thermal insulated blocks are leading the way. More than just an alternative to traditional concrete, these energy-efficient building blocks are transforming the industry with their superior insulation, sustainability, and cost-effectiveness.

But what exactly is a thermal block, and why is it becoming a game-changer in modern construction?

Table of Contents

What Are Thermal Insulated Blocks?

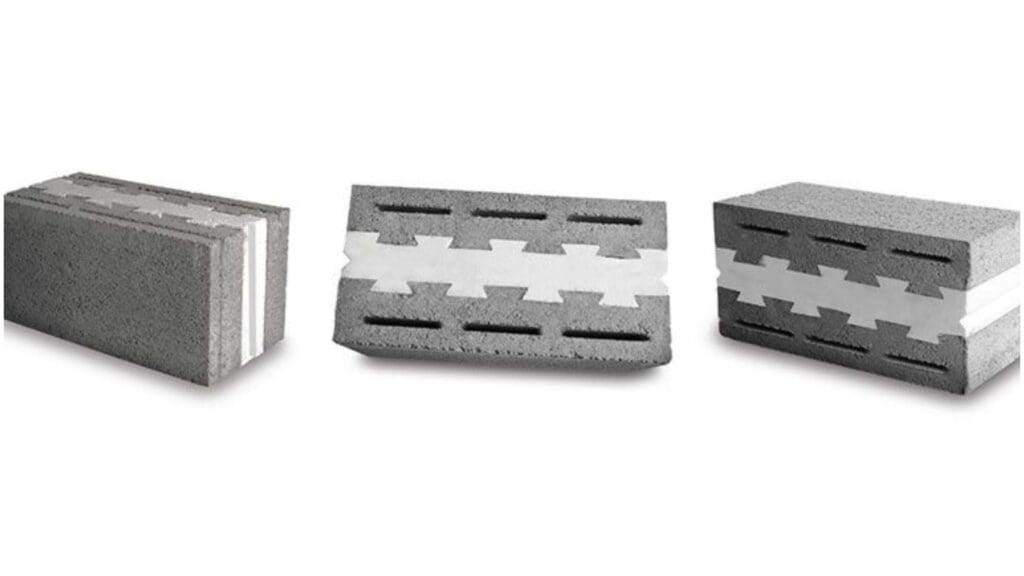

A thermal block is a high-performance building material that combines strength with insulation. These blocks are typically made with polystyrene, a lightweight yet durable material, embedded within concrete to enhance thermal resistance.

Unlike traditional concrete blocks, thermal insulated blocks provide both structural integrity and superior insulation, making them an ideal choice for energy-efficient buildings.

Why Builders Prefer Thermal Blocks

1. Energy Efficiency That Cuts Costs

One of the biggest thermal block uses is reducing energy consumption. Thanks to their low thermal conductivity, buildings made with these blocks stay cooler in summer and warmer in winter, slashing heating and cooling costs.

This efficiency helps lower electricity bills and reduces the carbon footprint—a win for both your budget and the environment.

2. Durability That Lasts Decades

Some assume lightweight materials are fragile, but thermal insulated blocks are built to last. They resist moisture, decay, and harsh weather, maintaining their strength for years with minimal maintenance.

This means lower repair costs and a longer-lasting structure—a key factor for both residential and commercial projects.

3. Cost-Effective in the Long Run

While thermal insulated blocks may have a higher upfront cost, their long-term savings make them an investment worth considering. Lower energy bills, reduced maintenance, and a longer building lifespan all contribute to their cost-effectiveness.

For developers looking for sustainable and economical solutions, thermal blocks offer unmatched value.

How Thermal Blocks Compare to Other Types of Blockwork

Construction relies on various types of blockwork, from concrete and aerated blocks to insulated thermal blocks. So, what sets thermal blocks apart?

- Traditional concrete blocks: Strong but lack insulation, leading to higher energy costs.

- Aerated blocks: Lighter and provide some insulation but are not as structurally strong.

- Thermal insulated blocks: The best of both worlds—offering strength and insulation, making them the preferred choice for energy-efficient construction.

The Rise of Thermal Blocks in GCC

With extreme temperatures and a growing demand for energy-efficient construction, the Gulf Cooperation Council (GCC) region—including Saudi Arabia, UAE, Qatar, Bahrain, and Oman—is rapidly embracing thermal insulated blocks as a superior building solution.

As a leading polystyrene manufacturer in the GCC, Forma Insulation provides high-performance insulation solutions tailored for the region’s construction needs. Our Block Insulation Inserts, made from Expanded Polystyrene (EPS), are designed to fit seamlessly into the hollow cores of cement blocks. This lightweight yet durable solution significantly enhances thermal insulation, reducing energy consumption in both residential and commercial buildings.

By using locally manufactured EPS insulation, builders not only benefit from superior thermal performance but also lower transportation costs, ensuring a sustainable and cost-effective approach to modern construction.

The Future of Thermal Insulated Blocks

Despite their benefits, thermal insulated blocks still face challenges—mainly higher initial costs and lack of awareness. However, as energy efficiency becomes a priority in construction, their adoption is rapidly increasing.

At Forma Insulation, we are committed to driving this change by delivering cutting-edge polystyrene insulation solutions that enhance building performance, reduce energy costs, and promote sustainable development.

Final Thoughts

Thermal insulated blocks are more than just an alternative to concrete—they are redefining how we build. With benefits like energy efficiency, durability, cost savings, and sustainability, they’re quickly becoming the go-to solution for modern construction. By integrating EPS Block Insulation Inserts, builders across Saudi Arabia, UAE, Qatar, Bahrain, and Oman can achieve superior insulation, long-term cost savings, and a reduced carbon footprint.

As innovation continues and polystyrene manufacturers in GCC we push boundaries, thermal blocks will shape the future of eco-friendly and energy-efficient buildings.

Looking to integrate thermal blocks into your next project?

REQUEST A QUOTE today and take the first step toward smarter, sustainable construction!

FAQ

1. What are thermal blocks, and why should I use them?

Thermal blocks are special building materials that keep heat from escaping or entering a building. They’re great for saving energy and keeping your space comfortable, especially in hot climates like the GCC.

2. How do your Block Insulation Inserts work?

Our inserts fit into the hollow centers of cement blocks, making them better at insulating. This means your building stays cooler in the summer and warmer in the winter, reducing your energy bills.

3. Why use EPS for insulation?

EPS is lightweight, strong, and great at holding in heat. It’s also locally made, which means lower shipping costs and a more sustainable choice for your projects.

4. How do thermal blocks compare to regular blocks?

Thermal blocks work much better at keeping heat out or in, so they help save energy. Traditional blocks don’t provide as much insulation, meaning higher energy costs.

5. Are there any downsides to thermal blocks?

They can be a bit more expensive upfront, and not everyone knows about them yet. But as energy-saving and eco-friendly options become more important, more people are starting to use them.